Forced Draft Fan working and Principle

A forced draft fan (FD fan) is a fan that is used to push air into a boiler or other combustion chamber. It is located at the inlet of the boiler and creates a positive pressure in the combustion chamber, which helps to ensure that the fuel burns properly.

The working principle of a forced draft fan is based on the Bernoulli principle, which states that the pressure of a fluid decreases as its velocity increases. The fan blades rotate and impart momentum to the air, which causes the air to accelerate. This acceleration of the air creates a lower pressure at the outlet of the fan, which draws air in from the inlet.

The amount of air that is pushed into the boiler by the FD fan is determined by the fan’s capacity and the pressure differential between the inlet and outlet of the fan. The fan’s capacity is the amount of air that it can move per unit of time, and the pressure differential is the difference in pressure between the inlet and outlet of the fan.

The FD fan is an essential component of any boiler system. It helps to ensure that the fuel burns properly and that the boiler operates efficiently.

Here are some of the benefits of using a forced draft fan:

- Improved combustion efficiency: The FD fan helps to ensure that the fuel burns completely, which results in improved combustion efficiency.

- Reduced emissions: The FD fan helps to reduce emissions by ensuring that the fuel burns completely.

- Increased boiler capacity: The FD fan can increase the capacity of the boiler by providing more air for combustion.

- Improved safety: The FD fan helps to improve safety by preventing the buildup of flammable gases in the boiler.

Forced Draft Fan ( Full form of FD Fan) is a type of fan supplying pressurized air to a system. In the case of a Steam Boiler Assembly, this FD fan is of great importance. The Forced Draft Fan (FD Fan) plays a crucial role in supplying the necessary combustion air to the steam boiler assembly, ensuring efficient and optimal combustion processes. Its pressurized airflow promotes the complete and controlled burning of fuel, enhancing the overall performance of the system.

What is the FD fan in a boiler?

In a boiler system, the FD fan, or Forced Draft Fan, plays a crucial role in ensuring efficient combustion and proper air circulation within the boiler. Its primary function is to supply the combustion air needed for the combustion process.

The FD fan works by drawing in ambient air and then forcing it into the combustion chamber, creating the necessary air-fuel mixture for the combustion process. This controlled air supply ensures that the fuel burns efficiently, leading to optimal heat transfer and energy production.

In summary, the FD fan is a vital component in a boiler system, responsible for providing the necessary air for combustion, contributing to the overall efficiency and performance of the boiler.

Forced Draft Fan (FD Fan) in Boilers

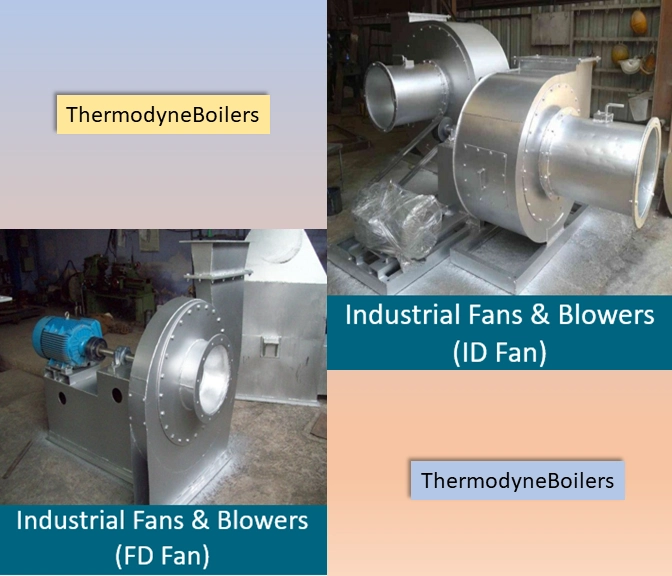

ID Fan & FD Fan

As we know, for a Steam Boiler to generate steam, combustion must occur, be it any fuel (wood/coal/rice husk/pet coke/LDO/Furnace oil), and for combustion to exist one of its three main requirements, is the air. And this requirement is compensated by a Forced Draft Fan. A Forced Draft Fan is essential in a steam boiler as it ensures a constant supply of air for combustion, promoting efficient fuel burning and steam generation. It helps maintain the optimal air-fuel ratio, ensuring the safe and reliable operation of the boiler.

FD Fan Working Principle

FD fan supplies air to the Air-preheater, where it captures the heat from the flue gases coming from the Boiler Outlet.

Nowadays, fluidized bed combustion is one of the promising ways of collecting more energy through combustion for solid fuels. But this wouldn’t have even been so famous if there wasn’t any Forced Draft Fan.

Whether it is a Bubbling or Circulating fluidized bed combustion incorporated Boiler. This phenomenon of fluidization is achieved through a Forced Draft Fan only.

Let us consider Bubbling Fluidized Combustion, Proper designing of the Fan as per the weight of the sand placed on the bed is very essential.

The pressurized air supplied by the Fan helps in providing enough draft equalizing the weight of the bed and the quantity to be supplied, hence creating fluidization of the sand in the furnace.

Not only the pressure head but also the quantity of air supplied for combustion needs to be calculated.

Primary Air Fan, and Secondary Air Fan are the different names of Forced Draft Fan. They all may be installed in the same Steam Boiler Assembly but they all operate at different levels of flow (m3/hr) and Head generated (mmwc).

Sometimes excess air required for complete combustion is compensated by the same FD Fan or a separate FD Fan also known as Secondary Air Fan is installed to carry out the function.

Forced Draft in a fan occurs when the fluid handled by the fan (generally air), is retained beyond the atmospheric pressure.

Every fan designer must never underestimate the importance of the properties and composition of the fuel to be combusted and the bed height in the furnace.

Also Read: Industrial Fans & Blowers

Forced Draft Fan Manufacturer & Supplier in India

Thermodyne Engineering Systems have successfully designed, manufactured and supplied Force draft fans to almost all of our customers and have successfully installed and comissioned them for highly efficient boiler operation.

FD Fans Related FAQs

An FD fan, or forced draft fan, is a type of fan that is used to supply pressurized air to a system. In the case of a steam boiler, the FD fan is responsible for supplying air to the furnace for combustion.

The full form of an FD fan is a forced draft fan.

The function of an FD fan in a boiler is to supply air to the furnace for combustion. The FD fan creates a positive pressure in the furnace, which helps to ensure that the fire burns efficiently.

There are several benefits to using an FD fan in a boiler.

These benefits include:

Improved combustion efficiency

Reduced emissions

Increased boiler lifespan

Reduced operating costs

There are two main types of FD fans: centrifugal fans and axial fans. Centrifugal fans are the most common type of FD fan. They work by using centrifugal force to accelerate the air, which then flows out of the fan at a higher pressure. Axial fans are less common than centrifugal fans. They work by using the fan blades to move the air in a straight line.

There are several factors to consider when choosing an FD fan. These factors include:

The size of the boiler

The type of fuel being burned

The desired combustion efficiency

The desired emissions levels

The operating costs

FD fans are typically installed in the flue gas duct of a boiler. The fan is connected to the duct by a flexible coupling. The fan is then secured to the duct with brackets.

FD fans should be maintained on a regular basis. This includes inspecting the fan for wear and tear, and cleaning the fan to remove dust and debris.

The most common problems with FD fans are:

Motor failure

Bearing failure

Fan blade damage

Vibration

If you are experiencing problems with your FD fan, there are a few things you can do to troubleshoot the problem. These things include:

1. Motor voltage of the fan

2. Speed of the fan

3. Check that fan bearings are in a good shape

4. Check if there is any damage or deformation in fan blades

5. Make sure the duct

Because it is rightly said in Boilers Industry = “A Happy Fan, Makes a Happier Boiler”