Boilers are devices that generate steam or hot water to provide heating and/or power for various industrial, commercial, and residential applications. There are several types of boilers, each with its own design, operation, and application

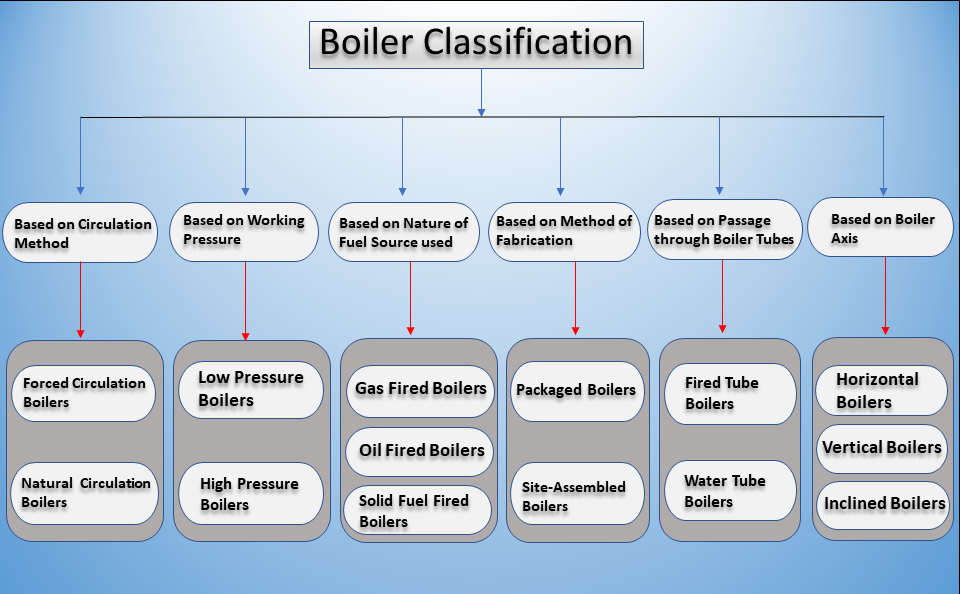

Boilers can be classified in various ways based on factors such as tube content, tube count, furnace placement, shell orientation, water and steam circulation methods, and intended use.

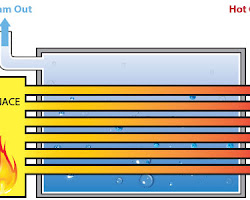

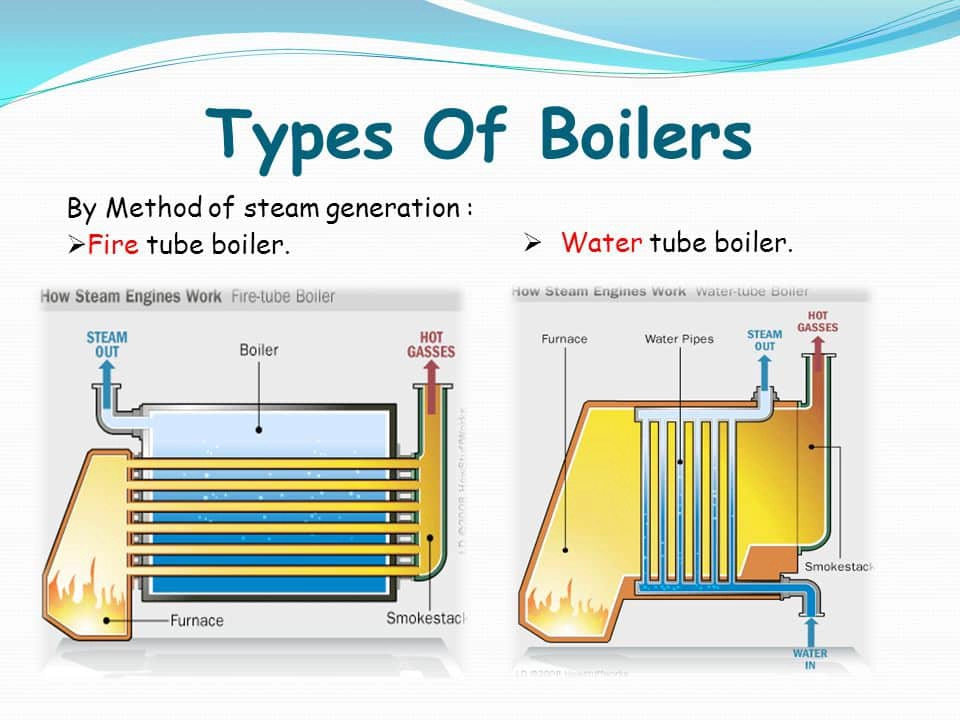

One common type is the Fire Tube Boiler. In this type, hot gases flow through long steel tubes while water circulates around these tubes, converting into steam.

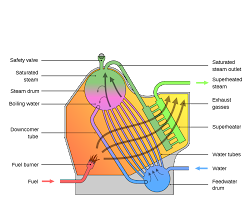

Another classification is the Water Tube Boiler. It is distinguished by water-filled tubes that are heated externally by hot gases. The resulting steam is then collected in a steam Fire tube or smoke tube boilers are also referred to as Shell Tube Boilers. These boilers have long steel tubes through which hot gases pass, while water circulates around the tubes to generate steam.

Types of Boilers Explained

There are many different types of boilers available in the market, each with its own purpose and application. As technology has advanced, more efficient boilers have replaced older, less efficient models. This article will discuss the different types of boilers and their classifications.

- Conventional boilers are the most common type of boiler. They have a firebox where fuel is burned, and the hot gases from the firebox pass through tubes that are surrounded by water. The water is heated and then circulated through radiators or other heating appliances. Conventional boilers are reliable and can provide a lot of hot water, but they can be less energy-efficient than newer models.

- Combi boilers are a newer type of boiler that combines the functions of a boiler and a hot water cylinder. This means that they can heat water directly from the mains, without the need for a separate hot water cylinder. Combi boilers are more energy-efficient than conventional boilers and take up less space.

- System boilers are similar to conventional boilers, but they do not require a cold water storage tank. This makes them a good option for homes with limited space. System boilers can provide hot water to multiple outlets simultaneously, but they may not be as energy-efficient as combi boilers.

- Condensing boilers are the most energy-efficient type of boiler. They recover heat from the exhaust gases, which can further reduce energy consumption. Condensing boilers are a good option for homeowners who want to save money on their energy bills.

- Biomass boilers use organic materials such as wood pellets, logs, or agricultural waste as fuel. They are a sustainable heating option that can help to reduce carbon emissions. Biomass boilers are a good choice for homeowners who are looking for a green alternative to traditional fossil fuels.

- Heat pump boilers use renewable energy from the air or ground to heat water. They are more efficient than conventional boilers and can help to reduce energy bills. Heat pump boilers are a good option for homeowners who want to save money and the environment.

- Electric boilers are powered by electricity. They are compact and easy to install, making them a good option for apartments or smaller homes. Electric boilers are not as energy-efficient as other types of boilers, but they can be a good choice for homeowners who do not have access to other fuel sources.’

Different Types of Boilers Used in Various Industries

Boilers are an indispensable component in industrial settings, delivering efficient heating and steam generation for a wide array of processes. They are available in various types, each tailored for specific applications and requirements. Gaining a comprehensive understanding of these diverse boiler types is crucial for industries seeking to make informed decisions in fulfilling their heating needs. In this article, we will delve into the different types of boilers commonly used in various industries, such as firetube boilers, watertube boilers, electric boilers, and biomass boilers. By exploring the unique features, advantages, applications, and practical considerations associated with each of these boiler types, we aim to equip professionals in manufacturing, power generation, and any other heat-dependent sectors with the knowledge needed to select the most suitable boiler for their specific requirements.

The best type of boiler for you will depend on your specific needs and requirements. Consider factors such as the size of your home, your hot water demand, your budget, and your environmental concerns when making your decision.

What are the different classification of boilers?

Boilers can be classified in various ways based on factors such as tube content, tube count, furnace placement, shell orientation, water and steam circulation methods, and intended use.

One common type is the Fire Tube Boiler. In this type, hot gases flow through long steel tubes while water circulates around these tubes, converting into steam.

Another classification is the Water Tube Boiler. It is distinguished by water-filled tubes that are heated externally by hot gases. The resulting steam is then collected in a steam drum.

Sometimes, Fire tube or smoke tube boilers are also referred to as Shell Tube Boilers. These boilers have long steel tubes through which hot gases pass, while water circulates around the tubes to generate steam.

These examples highlight the diverse range of boiler classifications and types. Each type has its own unique advantages and applications, catering to specific requirements. Consulting with a professional or referring to reliable sources is recommended for more detailed information.

Type Of Steam Boiler & Different Type Of Boilers

Fire tube boilers: These boilers are the most common type of steam boiler. They have a firebox where fuel is burned to heat water. The hot water then flows through tubes that are surrounded by hot gases. The most common type of fire tube boiler is the locomotive boiler.

Water tube boilers

In water tube boilers, the water flows through the tubes and the hot gases flow around the tubes. This type of boiler is more efficient than fire tube boilers and can generate more steam.

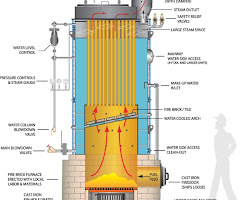

Vertical boilers

Vertical boilers are typically used for small applications, such as residential heating. They are compact and easy to install.

Horizontal boilers

Horizontal boilers are typically used for larger applications, such as industrial heating. They are more efficient than vertical boilers.

Package boilers

Package boilers are factory-assembled boilers that are ready to install. They are a convenient option for small businesses and homeowners.

Condensing boilers

Condensing boilers are the most efficient type of steam boiler. They recover heat from the steam condensation, which can increase efficiency by up to 20%.

The best type of steam boiler for you will depend on your specific needs and requirements. Consider the size of your application, the fuel you will use, and your budget.

Industrial boilers are closed vessels requiring a fuel source or electricity in order to heat water or produce steam regarding industrial heating and humidification applications. Industrial Steam boilers are high-volume closed vessels that utilize fuel sources or electricity to efficiently heat water and generate large quantities of steam for industrial heating and humidification applications.

Type Of Boiler Classification Diagram

Industrial boiler imparts heat and power for a variety of systems and applications in several industries. Listed below are some common industries & applications of steam boilers. They play a crucial role in sectors such as manufacturing, where steam boilers are used for heating and powering machinery and equipment. Additionally, steam boilers find applications in the food processing industry, facilitating processes like cooking, sterilization, and pasteurization to ensure product safety and quality.

- Agriculture Soil Steaming

- Turbines

- Steam Generation

- Cement Production

- Kilns

- Sugar industries

- Paper industries

- Pulp industries

- Diaries

- Ceramic material testing

- Food processing industry

- Rubber Industry

- Industrial Steam Boiler Manufacturer

The motto of industrial boilers using in industries is doing a variety of things such as paper and pulp, metalworking, refining, electrical, and refining, and food and beverage.

Types of Steam Boilers

Talking about the basic concept of a Type of boiler, it needs a heat source and a heat exchanger /heat transfer medium allowing water to be heated more than its boiling point.

Source: SlidePlayer: steam boiler types

Types of Steam Boilers

Moreover, the type of heat source and the method of heat exchange are considered different types of steam boilers.

Industrial boilers come in different types. Moreover, you can choose on the basis of different aspects such as function, technology, heat, and source.

Types of Boilers Based on Function

- Hot water boilers are used to heat water for hydronic, which are needed for domestic, and commercial both uses. It could be needed for various purposes such as

- Freeze Protection,

- Commercial Dishwashers,

- Radiant Floor Heating,

- Hot Water Needs,

- Comfort Heating,

- Car Washes,

- Steam boilers heat hot water required for producing steam to accomplish various job applications such as

- Turbines For Power Generation,

- Various Industrial Heating Applications

- Agricultural soil steaming.

Boiler Types Based on Design

You may not find it a bit bizarre but true that boilers can also be distinguished based on boiler design and construction.

- Fire-tube boilers are used in order to add hot gases from the heating source through tubes attached inside a water-filled drum so that heat could be transformed into water.

- Horizontal return tubular (HRT)boilers are generally held in a horizontal shape having self-contained fire tubes along with a separate combustion chamber.

Apart from it, there are Scotch, Scotch marine, and Firebox boilers on the list having all sorts of features.

Steam Boilers types based on Combustion Technology

These combustion technology-oriented boilers have been designed going with the technology emphasizing the way of using burn or heat a specific fuel source.

They are designed in a way to maximize the entire performance. They are many types available going with combustion technology such as

- Fluidized Bed

- Stoker

- Spreader

- Traveling-grantor chain-grate

- Thermic fluid heaters

Types Of Boilers Based on Heat Source

Talking about other sources, there are some other key aspects that differentiate boilers is the heat source used. There are different types of heat sources used to have incredible job applications such

- Coal – This kind of boiler is used for different types of job applications related to industry and that is why it is called industrial boilers. Generally, pulverized coal which is coal ground to a fine powder is used for it. The best thing is that this coal type is used more than larger clumps of coal.

- Biomass– Next one on the list is fuel categorized to all sorts of burnable organic materials such as

- Rice Husk

- Wood Chips,

- And Other Agricultural Waste Products.

- Gas – This one category is actually belonging to operating on the basis of using either natural gas or propane.

- Oil -These boilers work on the basis of oil fuel sources such as gasoline or other petroleum-based fluids.

- Hydronic– These boilers are used going with steam considering as the heat source. In these boilers, heat is transferred from the steam.

- Wood – Itis a fuel source used that goes with traditional boiler designs. It is used for various purposes.

Boilers generally go with the following component such as a combustion system including oil, gas, coal, electricity and biomass, tubes and containment areas for water or steam. Boilers also feature different types of components including safety, water gauges, pressure gauges, low water alarms, stop valves and so on.

Boiler safe and compliance standards have actually been well defined and they are manufactured and made accordingly. Boilers should also meet EPA standards. Here, it needs to mention that your boiler is subjected to industry and application-specific standards as well.

Are you looking for an industrial boiler?

You just need to go with a qualified customer boiler manufacturer. You need to consider that not all companies come up with an equal methodology to prepare standard quality boilers. Make sure that you are going to buy the right boiler as per your job application demands. It helps to get the best results. You may check out online to grab more information regarding this in a detailed manner.

And these are prominent types of boilers having different designs, types, and fuel types. To find the best boiler as per the accurate feature.

Right Steam Boiler for Your Needs FAQ

There are many different types of boilers, but they can be broadly categorized into two main types: water boilers and steam boilers.

Water boilers heat water to produce hot water for heating and/or domestic hot water.

Steam boilers heat water to produce steam, which can be used for heating, power generation, or industrial processes.

The main difference between a water boiler and a steam boiler is the state of the water that is heated. In a water boiler, the water is heated to a high temperature, but it does not boil. In a steam boiler, the water is heated to a high temperature and it turns into steam.

Boiler systems offer a number of benefits, including:

Efficiency: Boilers can be very efficient, meaning that they can produce a lot of heat with a relatively small amount of fuel.

Comfort: Boilers can provide a comfortable and consistent source of heat, even in cold weather.

Versatility: Boilers can be used for a variety of purposes, including heating, hot water, and power generation.

Boiler systems can pose a number of risks, including:

Fire: Boilers can overheat and cause fires.

Burns: Boilers can produce steam that can cause burns.

Explosion: Boilers can explode if they are not properly maintained.

When choosing a boiler, it is important to consider the following factors:

The size of your home or business: The size of your boiler will need to be large enough to heat your home or business.

The climate in your area: Boilers that are designed for cold climates will need to be more powerful than boilers that are designed for warm climates.

The type of fuel you want to use: Boilers can be powered by a variety of fuels, including natural gas, propane, oil, and wood.

Your budget: Boilers can range in price from a few hundred dollars to several thousand dollars.

Boiler installation should be done by a qualified professional. Improper installation can lead to safety hazards

Boiler maintenance is important to ensure that your boiler is safe and efficient. Regular maintenance includes:

Checking the water level: The water level in your boiler should be checked regularly and topped off as needed.

Cleaning the boiler: The boiler should be cleaned regularly to remove sediment and other debris.

Inspecting the boiler: The boiler should be inspected regularly for signs of wear and tear.

If you have problems with your boiler, it is important to troubleshoot the problem before trying to fix it yourself. If you are not comfortable troubleshooting the problem, you should call a qualified professional.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast of the Semantics, a large language ocean.

There are many resources available to learn more about boilers. You can find information online, in books, and from qualified professionals.

Boiler Resources Page Link

Boiler Losses That Eat Away Your Profits

Dissolved Gases in Feed Water and Its Effect

Pressure Reduction System

How to Minimize the Blowdown Losses

Get More Learn About Our Boiler Product Blog Page

Industry Boiler Spare Parts Manufacturer

J&K

Uttarakhand

Rajasthan

Punjab

Haryana

Chhattisgarh

Uttar Pradesh

Bangladesh

Sri Lanka

Bihar

Delhi