Steam Superheaters in Industrial Boilers

The Steam Superheater is a coil-type heat exchanger which is used to produce superheated steam or to convert the wet steam to dry steam, generated by a boiler. The superheater is typically located in the flue gas path of the boiler, where it is heated by the hot flue gases. The superheater can be made of a variety of materials, including steel, copper, and stainless steel.

It is different from a boiler in a way that a boilers utilizes both sensible heat as well as latent heat to convert water into steam while a superheater utilizes only sensible heat to superheat the steam in order to increase its enthalpy. Therefore, a superheater is a type of heat exchanger that is used to increase the temperature of steam without changing its pressure.

What is a superheater in boiler and main function?

A superheater in a boiler is a device that elevates the temperature of steam produced by the boiler, converting it from saturated steam to superheated steam. Saturated steam exists at its boiling point for a given pressure, while superheated steam has been heated beyond its boiling point.

The primary function of a superheater is to increase the steam’s temperature, utilising the heat from the combustion gases to further heat the steam and elevate its temperature. This process offers several advantages, including:

Enhanced energy transfer: Superheated steam possesses higher thermal energy compared to saturated steam, enabling more efficient heat transfer in industrial applications.

Improved turbine efficiency: Superheated steam finds application in steam turbines for electricity generation. Its elevated temperature and energy content translate into improved turbine efficiency and enhanced power generation.

Reduced moisture content: Superheated steam exhibits lower moisture content compared to saturated steam, making it ideal for applications that demand dry steam, such as steam-based processing systems.

By increasing the temperature of steam and enhancing its properties, the superheater plays a crucial role in improving the overall efficiency and performance of the boiler system.

There are three main types of superheaters:

- Radiant superheaters: Radiant superheaters are located in the furnace chamber of the boiler, where they are directly exposed to the radiant heat from the flames. Radiant superheaters are typically used to superheat steam to high temperatures.

- Convection superheaters: Convection superheaters are located in the flue gas path of the boiler, where they are heated by the hot flue gases. Convection superheaters are typically used to superheat steam to lower temperatures than radiant superheaters.

- Separately fired superheaters: Separately fired superheaters are external to the boiler and have their own furnace. Separately fired superheaters are typically used to superheat steam to very high temperatures.

Boiler Superheaters: Material Selection for Optimal Performance

Superheaters are critical components of boilers, responsible for converting saturated steam into superheated steam, a high-energy steam form that drives turbines for electricity generation and various industrial applications. The material selection for superheater construction is crucial as it directly impacts the component’s durability and performance under extreme temperature and pressure conditions.

Factors Influencing Material Selection

The choice of superheater material is guided by several factors, including:

- Steam Temperature: As steam temperature increases, the material must possess higher strength and creep resistance to withstand the elevated thermal stresses.

- Pressure: Superheaters operate under high pressures, demanding materials with exceptional pressure containment capabilities.

- Corrosion Resistance: The superheater environment can be corrosive due to the presence of combustion gases and impurities in the steam. The chosen material must exhibit adequate corrosion resistance to maintain integrity over extended service periods.

Common Superheater Materials

Based on the aforementioned factors, a range of steel alloys are commonly employed in superheater construction:

- Carbon Steel: Used for low-temperature superheaters, carbon steel offers a balance of strength, cost-effectiveness, and weldability.

- Low Alloy Steel: For moderate temperature applications, low alloy steel provides enhanced creep resistance and strength compared to carbon steel.

- High Alloy Steel: High alloy steels, such as T91 and T23, cater to superheaters operating at high temperatures and pressures. These alloys offer exceptional creep resistance, high-temperature strength, and oxidation resistance.

- Stainless Steel: Austenitic stainless steels, such as TP304 and TP316, are employed in superheaters exposed to corrosive environments or handling high-purity steam

Benefits of Superheaters in Boilers

- Increase in efficiency of the steam power plant

- Minimized erosion of turbine blade

- Less steam consumption

- Reduction of condensation loss in the boiler steam pipes

- Increases the temperature of saturated steam by removing entrained water particles from turbines steam

Use of Superheaters in Industrial Boilers

- Superheaters are used where only dry steam is required in a process/machines such as Turbines. Any moisture content in a steam in such cases happens to degrade or corrode the machine thereby affecting its average operating life. So, the superheater converts low-quality steam to high-quality for end users.

- Sometimes, a superheater is also needed when we need to transport steam to far-off places as there are some temperature losses during its transportation.

- Superheaters can be used in a steam engine where absolute dry steam is needed to prevent wear and tear of engine parts.

- In case of water tube boilers, hot gases will provide the required temperature to produce superheated steam and superheater may be an additional part of the furnace area. In other cases, separately fired superheater may be required because gas turbine produced gases are relatively cool.

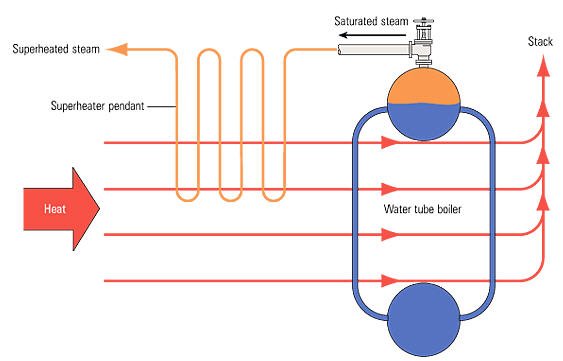

Superheater in Boiler Diagram

Boiler Superheater's Manufacturing

Our superheaters are manufactured according to the IBR Regulations. Thermodyne manufactures both coil type and shell type superheaters depending upon the type of boiler and boiler capacity.

Coil type superheaters design generally consists of 180o coils welded through the headers on both the sides. In a coil type designs steam is inside the coil and flue gases are outside the coil.

Shell type superheaters design generally used to superheat the steam electrically using special heating elements stacked in a shell and the steam flows over the heating elements.

Designing Parameters of Industrial Superheaters

- Boiler pressure

- Steam pressure

- Temperature requirement in the process

Types of Superheater in Boiler

Depending upon the steam temperature requirement, Superheaters are divided into two parts:

Radiant Superheaters

Radiant superheaters are the type of superheaters that are installed in a radiation zone just after the furnace. In high-pressure boilers when the temperature difference in saturated and superheated steam is around 100oC. Superheaters must be installed in a radiant zone.

Convective Superheaters

Convective superheaters are installed after the convective bank of tubes. When the temperature difference between saturated and superheated steam is not more than 50oC. Superheaters must be installed in a convective zone.

Steam Superheater in Boiler Manufacturer in India

Reasons to buy steam superheater from Thermodyne-

- Our boiler superheaters come with adequate safety features to prolong the life of a superheater as well as your equipment where the steam is used.

- The safety valve is installed in a super-heater to prevent operating pressure to exceed the design pressure of a superheater in the boiler.

- We manufacture steam superheaters that suit different type of fuels such as:

- Solid Fuels (Wood, Rice Husk, Bagasse, Coal)

- Liquid and Gas fuels (Light and Heavy Oils, Natural Gas)

- Electrical operated steam boiler superheaters.

Also Read: Air Pollution Control Equipment

Looking for boiler superheater manufacturers?

Contact us for the best steam process solution. You can trust us as one of the best boiler manufacturers in India.

Steam boiler Superheater FAQs

A superheater is a device used to convert saturated steam or wet steam into superheated steam or dry steam. Superheated steam is used in steam turbines for electricity generation, steam engines, and in processes such as steam reforming.

There are three main types of superheaters: radiant, convection, and separately fired. Radiant superheaters are heated by the radiant heat of the combustion gases. Convection superheaters are heated by the convection currents of the combustion gases. Separately fired superheaters are heated by a separate burner.

The function of a superheater in a boiler is to increase the temperature of the steam above its saturation temperature. This is done in order to improve the efficiency of the steam turbine and to prevent the formation of steam pockets in the turbine.

There are several benefits to using a superheater, including:

Increased efficiency of the steam turbine

Reduced risk of steam pockets in the turbine

Improved reliability of the steam turbine

Increased lifespan of the steam turbine

There are a few drawbacks to using a superheater, including:

Increased cost of the boiler

Increased complexity of the boiler

Increased maintenance requirements of the boiler

The factors to consider when selecting a superheater include:

The type of boiler

The steam pressure and temperature requirements

The desired efficiency of the steam turbine

The budget

superheater is installed in the boiler after the economizer and before the steam drum. The superheater tubes are typically made of stainless steel or carbon steel. The superheater is usually installed in the flue gas path of the boiler.

A superheater should be inspected and maintained on a regular basis. The inspection should include a visual inspection of the superheater tubes for cracks or leaks. The maintenance should include cleaning the superheater tubes to remove any deposits that may have accumulated.

Tube leaks

Tube corrosion

Tube erosion

Tube blockage

Maintaining the boiler at the correct water level

Maintaining the boiler at the correct steam pressure and temperature

Avoiding excessive soot buildup in the boiler

A superheater in a boiler is a device that further heats steam to a higher temperature, increasing its energy content and improving efficiency.

Boiler Losses That Eat Away Your Profits

Dissolved Gases in Feed Water and Its Effect

Pressure Reduction System

How to minimize the Blowdown Losses

Steam Superheater