Power of Piston Pumps in Supplying Feed Water to Boilers

Piston Pumps in Supplying Feed Water to Steam Boilers

Piston pump supplies feed water to the steam boiler as and when required. Piston Pumps are used to effectively control the amount of water supplied to the Industrial steam boilers. These pumps are provided with dimension-ally accurate. we are providing clients high quality Industrial Boiler Piston Pump. Thermodyne is a supplier of steam boiler piston pump.

Boiler Piston pumps play a crucial role in efficiently controlling the supply of feed water to boilers. At Thermodyne, we take pride in offering high-quality Steam boilers piston pumps that are dimensionally accurate and designed to meet the specific needs of our clients. In this comprehensive article, we will explore the significance of Steam boilers piston pumps and how they contribute to the smooth functioning of Industrial Steam boilers.

1. Introduction to Steam Boiler Piston Pumps

Piston pumps are positive displacement pumps that use reciprocating pistons to move fluid. These pumps are known for their ability to handle a wide range of liquids, including water. They are commonly used in various industries, including power generation, oil and gas, chemical processing, and more. When it comes to supplying feed water to boilers, piston pumps offer reliable performance and precise control.

2. The Role of Piston Pumps in Boiler Systems

In a Steam boiler system, the piston pump plays a vital role in maintaining the water level. It supplies water to the Industrial boiler as and when required, ensuring the optimal functioning of the entire system. The pump works by drawing water from a source, such as a storage tank or a water treatment system, and delivering it to the boiler. By controlling the water flow, piston pumps help regulate the pressure and maintain the desired water level in the Steam boiler.

3. Advantages of Using Piston Pumps in Boiler Applications

3.1 Precise Control

Piston pumps offer excellent control over the water supply to the industrial boiler. Their reciprocating motion allows for accurate metering, ensuring the right amount of water is supplied at all times. This precise control is essential for maintaining the optimal water level and preventing any potential issues such as overheating or inadequate water supply.

3.2 Reliability and Durability

At Thermodyne, we understand the importance of reliable equipment in industrial applications. Our steam boiler piston pumps are designed with high-quality materials and undergo rigorous testing to ensure their durability and longevity. With minimal maintenance requirements, our pumps provide reliable performance, reducing downtime and optimizing overall system boilers efficiency.

3.3 Energy Efficiency

Energy efficiency is a crucial factor in today’s industrial landscape. Piston pumps are known for their energy-efficient operation, which helps in reducing power consumption and minimizing operational costs. By choosing our high-quality boilers piston pumps, you can achieve optimal energy efficiency in your boiler system, enhancing sustainability and profitability.

4. The Thermodyne Advantage

Thermodyne is a trusted supplier of boiler piston pumps, offering cutting-edge solutions to meet the diverse needs of our clients. When you choose our piston pumps, you benefit from:

4.1 Customized Solutions

We understand that each steam boiler system has unique requirements. Our team of experts works closely with clients to understand their specific needs and provide customized piston pump solutions that deliver optimal performance.

4.2 Superior Quality

Quality is at the core of our offerings. Our Boilers piston pumps are manufactured using the latest technology and adhere to stringent quality standards. We prioritize precision and accuracy to ensure that our pumps provide reliable and long-lasting performance.

4.3 Technical Support

At Thermodyne, we believe in providing excellent customer support throughout the entire lifecycle of our products. Our team of skilled technicians is available to assist you with any technical queries or assistance you may require, ensuring a seamless experience.

Steam boilers Piston pumps are indispensable in boiler applications, enabling precise control over the feed water supply. At Thermodyne, we take pride in offering high-quality boiler piston pumps that deliver reliable performance, energy efficiency, and durability. With our customized solutions and commitment to customer satisfaction, we aim to be your trusted partner in optimizing your boiler system’s efficiency and productivity.

Piston Pumps Steam boiler FAQ:-

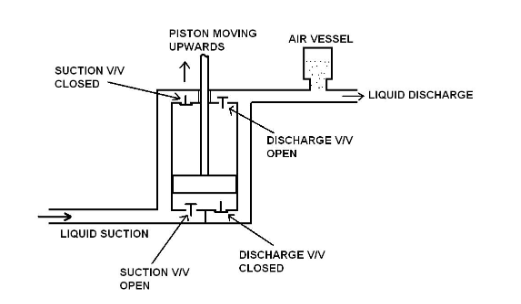

A steam boiler piston pump is a type of pump that is used to deliver feedwater to a steam boiler. The pump works by using a piston to move the feedwater through a series of chambers. The piston is driven by a motor, which creates a reciprocating motion. This motion causes the feedwater to be drawn into the pump, compressed, and then discharged.

There are two main types of piston pumps that are used in steam boilers: single-acting and double-acting. Single-acting piston pumps only have one piston, which moves in one direction. Double-acting piston pumps have two pistons, which move in opposite directions.

The process of a piston pump can be divided into four steps:

The piston moves down, creating a vacuum in the pump chamber.

Feedwater is drawn into the pump chamber.

The piston moves up, compressing the feedwater.

The feedwater is discharged from the pump chamber.

The most commonly used pump for boilers is the reciprocating piston pump. This type of pump is simple to operate and maintain, and it is relatively inexpensive. Reciprocating piston pumps are also capable of delivering high flow rates and pressures.

The disadvantages of using a piston pump for steam boilers include:

Cavitation can occur at high pressures

The pump can be noisy

The pump can be inefficient at low flow rates

The advantages of using a piston pump for steam boilers include:

Simple operation and maintenance

Low cost

Ability to deliver high flow rates and pressures

Durability

The factors to consider when choosing a piston pump for a steam boiler include:

The flow rate and pressure requirements of the boiler

The type of feedwater being used

The operating environment

The budget

The common problems with piston pumps for steam boilers include:

Cavitation

Wear and tear

Clogging

Leaks

The problems with piston pumps for Industrial steam boilers can be prevented by:

Using the correct type of pump for the application

Maintaining the pump properly

Using high-quality feedwater

The safety precautions to take when using a piston pump for Industrial steam boilers include:

Wearing safety glasses and gloves

Keeping the pump area clean and free of debris

Disconnecting the power to the pump before performing maintenance