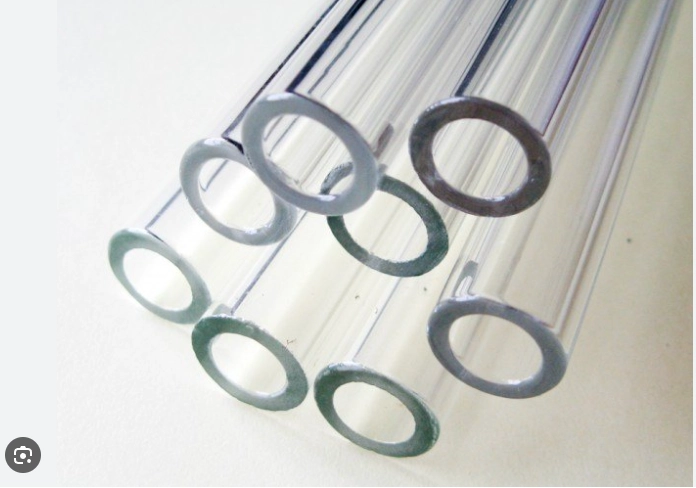

Industrial Steam Boilers Glass Tube

Our clients can avail from us a wide range of Steam Industrial Boiler Water Level Glass Tube which is made in high quality . These Steam Boilers Water Level Glass Tubes are widely appreciated by our clients.

The boiler industry is a vital sector that provides essential heat and energy for various applications. Over time, technological advancements have transformed the Steam boiler landscape, and one significant innovation making waves is the utilization of glass tubes. These transparent conduits are revolutionizing the industry, offering numerous benefits in terms of efficiency, safety, and sustainability.

We offer these Industrial Boiler Water Level Glass Tube at most affordable prices to our precious customers.

Benefits of Glass Tubes in Steam Boilers

- Enhanced Efficiency: Glass tubes allow operators to easily monitor the combustion process, fuel distribution, and heat transfer within the system. This real-time visibility allows for better control and optimization of steam boiler performance. By identifying inefficiencies or irregularities promptly, operators can make necessary adjustments, resulting in enhanced energy efficiency and reduced fuel consumption.

- Safety Advancements: Glass tubes offer a direct view into the combustion chamber, enabling operators to visually inspect the flame quality, detect potential issues like flame impingement or improper fuel-air mixture, and take immediate action to prevent accidents or breakdowns. This enhanced safety feature helps safeguard personnel, equipment, and the surrounding environment.

- Simplified Maintenance and Troubleshooting: Glass tubes simplify maintenance and troubleshooting processes in the boiler industry. Regular inspections can be conducted swiftly and efficiently by visually examining the interior components of the boiler through the transparent tubes. This eliminates the need for time-consuming disassembly and reassembly procedures, reducing downtime and associated costs. Glass tubes also aid in troubleshooting as they allow operators to pinpoint the source of a problem quickly. Whether it’s identifying fouling, scaling, or other operational issues, the clear visibility provided by glass tubes facilitates faster diagnosis and enables targeted interventions, streamlining maintenance activities.

- Environmental Sustainability: Glass tubes contribute to the sustainability goals of the Steam boiler industry. By providing real-time visibility and improved efficiency, they help reduce greenhouse gas emissions by optimizing the combustion process. Operators can closely monitor the fuel-to-air ratio, ensuring clean and complete combustion, thereby minimizing the release of harmful pollutants. Moreover, glass tubes enable the integration of advanced emission control technologies, such as selective catalytic reduction (SCR) systems or flue gas desulfurization (FGD) units, by providing a direct view of the flue gas path. This transparency aids in proper placement and efficient operation of these technologies, further reducing environmental impact.

Industrial Steam Boiler Glass Tube FAQ

A boiler glass tube, also known as a sight glass or sight gauge, is a transparent tube that is installed in a steam boiler to allow operators to visually monitor the water level in the Industrial boilers. The tube is typically made of borosilicate glass, which is a type of glass that is resistant to thermal shock and chemicals.

A Industrial Steam boilers glass tube is necessary to ensure the safe and efficient operation of a steam boiler. By visually monitoring the water level in the boiler, operators can prevent the boiler from running dry, which can cause damage to the boiler and create a safety hazard.

The boilers glass tube is connected to the boiler’s water level control system. As the water level in the Industrial boiler rises and falls, the water level in the glass tube will also rise and fall. This allows operators to see the water level in the Steam boiler at a glance.

There are two main types of boilers glass tubes:

Direct-contact sight glasses: These sight glasses are in direct contact with the boiler water. This type of sight glass is the most common type and is relatively inexpensive.

Indirect-contact sight glasses: These sight glasses are not in direct contact with the boiler water. Instead, they are connected to the boiler water by a series of tubes. This type of sight glass is more expensive than direct-contact sight glasses, but it is also more durable and resistant to damage.

Industrial steam Boilers glass tubes should be cleaned regularly to remove any build-up of scale, dirt, or debris. This will help to ensure that the sight glass is clear and that the water level can be easily monitored.

There are a few signs that can indicate that your steam boiler glass tube is broken. These signs include:

The sight glass is cracked or leaking.

The sight glass is cloudy or discolored.

The sight glass is not clear enough to see the water level.

There are a few safety hazards associated with Industrial boiler glass tubes. These hazards include:

The glass tube steam boiler can break, which can cause serious injury or death.

The glass tube can become contaminated with chemicals or other substances, which can be harmful if ingested.

The glass tube can become blocked, which can prevent operators from seeing the water level.

It is important to take steps to minimize these safety hazards, such as:

Installing a protective shield around the glass tube.

Regularly inspecting the glass tube for cracks or leaks.

Cleaning the glass tube regularly.

Replacing a Industrial steam boiler glass tube is a relatively simple task that can be done by most homeowners. However, it is important to follow the manufacturer’s instructions carefully to avoid injury or damage to the boiler.

Having two type boiler glass tubes provides a number of benefits, including:

Increased safety: If one glass tube breaks, the other glass tube can still be used to monitor the water level.

Improved visibility: Two glass tubes provide a wider view of the water level, which can make it easier to see the level accurately.

Reduced maintenance: Two glass tubes can be inspected and cleaned less frequently than a single glass tube.

The only real disadvantage of having two boiler glass tubes is the increased cost. However, the benefits of having two glass tubes generally outweigh the cost.