What is the Thermal Power Plant

Thermal power plant are the most common type of power plant in the world, accounting for about 60% of global electricity generation. They are used to generate electricity from a variety of fuels, including coal, natural gas, oil, and nuclear power.

How does the presence of boilers contribute to the functioning of a Thermal Power Plant?

What is Working Of Thermal Power Plant

Thermal power plants are large-scale facilities that convert heat energy into electricity. They are the backbone of global electricity generation, providing around 60% of the world’s power. However, their reliance on burning fossil fuels raises environmental concerns.

The working principle of thermal power plants involves using heat to produce high-pressure steam, which drives turbines connected to generators. The steam is then condensed back into water and reused.

Despite their reliability and efficiency, thermal power plants are a major source of air pollution, emitting sulfur dioxide, nitrogen oxides, particulate matter, and greenhouse gases like carbon dioxide.

As the world transitions towards cleaner energy sources, thermal power plants need to adapt to reduce their environmental impact. This can be achieved by switching to cleaner fuels like natural gas and implementing advanced pollution control technologies.

In essence, thermal power plants play a crucial role in electricity generation but need to evolve to address their environmental impact.

1. Heat Generation: The process begins by generating intense heat. This can be achieved by burning fossil fuels like coal, natural gas, or by harnessing nuclear reactions. In your industry, you may also use electric boilers for this purpose.

2. Boiling Water: This intense heat is then used to boil water within a high-pressure vessel. This results in the formation of high-pressure steam. The steam is like a powerful force waiting to be harnessed.

3. Steam Turbine: The high-pressure steam is directed towards a steam turbine. This is a bit like a giant fan that’s turned by the force of the steam. As the turbine spins, it drives an electrical generator.

4. Generating Electricity: The generator is where the magic happens. As it turns, it produces electricity. This electricity is then sent out to power homes, industries, and more.

5. Recycling Heat: But the process doesn’t end there. After the steam has done its job, it exits the turbine at a lower pressure. It’s still hot, though. This hot steam is sent to a steam condenser.

6. Cooling and Recycling: In the condenser, the hot steam is cooled down, turning it into water again. This condensed water is then sent back to the high-pressure vessel to begin the cycle anew.

This continuous cycle of heat, steam, and electricity generation is the heart of a thermal power plant. It’s an efficient way to produce large amounts of electricity to meet our energy needs. In your industry, this knowledge is vital as you manufacture boilers that play a pivotal role in this process.

Thermal power plants are essential for providing electricity to homes, industries, and communities, making them a cornerstone of modern life.

Thermal Power Plant Station How does it Work

The most prevalent type of thermal power plant worldwide, responsible for approximately 60% of global electricity generation, is the Thermal Plant. These plants use Coal, Natural Gas, or Oil Fired Boilers to heat water, creating steam, which, in turn, powers a turbine connected to a generator to produce electricity.

Types of Thermal Power Plant:

Thermal power plants can be categorized into two primary types:

1. Conventional Thermal Power Plants: These facilities utilize a steam turbine for electricity generation. The steam is generated by combusting fuels such as coal, natural gas, or oil in a boiler.

2. Combined Cycle Thermal Power Plant: These plants employ both a gas turbine and a steam turbine for electricity generation. The gas turbine generates power in the initial phase, while the steam turbine is responsible for the subsequent electricity generation. The heat from the gas turbine is used to heat water and create steam for the steam turbine.

Advantages of Thermal Power Plants:

– They are relatively cost-effective to construct and operate.

– They come in various sizes, from small plants serving a single community to large plants capable of powering entire countries.

– They are reliable and can operate continuously for extended periods.

However, Thermal Power Plant have several drawbacks, including:

– The emission of greenhouse gases, particularly carbon dioxide, contributing to climate change.

– Air pollution with pollutants like sulfur dioxide and nitrogen oxides.

– High water consumption, which can be problematic in regions with limited water resources.

Notwithstanding these disadvantages, Thermal Power Plant continue to play a pivotal role in electricity generation in numerous nations. As the world transitions towards cleaner energy solutions, it becomes imperative to adapt and modify Thermal Power Plant to reduce emissions and environmental impact.

Principle of Thermal Power Plant

“Thermal power plant” as the title infers is the place of mechanism which converts heat energy into electric power.

A thermal power plant is a large facility that converts heat energy into electric power. The heat energy is typically generated by burning fossil fuels, such as coal, oil, or natural gas. The hot combustion gases are used to heat water in a Steam boiler, which produces steam. The steam is then used to turn a turbine, which is connected to an electric generator. The generator converts the mechanical energy of the turbine into electric power.Thermal power plants are a major source of electricity in the world. They are reliable and efficient, and they can be built on a large scale. However, they also have a number of environmental drawbacks, including air pollution and greenhouse gas emissions.

One way to reduce the environmental impact of thermal power plants is to use high-volume combustion technologies. These technologies allow for more efficient combustion of fuel, which reduces emissions. High-volume combustion technologies are also being used to develop new types of thermal power plants that use renewable energy sources, such as biomass and solar thermal energy.

Working of Thermal Power Plant

A thermal power plant is a large facility that converts heat energy into electric power. Heat energy is typically generated by burning fossil fuels, such as coal, oil, or natural gas. The hot combustion gases are used to heat water in a boiler, which produces steam. The steam is then used to turn a turbine, which is connected to an electric generator. The generator converts the mechanical energy of the turbine into electric power.

Thermal power plants are a major source of electricity in the world. They are reliable and efficient, and they can be built on a large scale. However, they also have a number of environmental drawbacks, including air pollution and greenhouse gas emissions.

One way to reduce the environmental impact of thermal power plants is to use high-volume combustion technologies. These technologies allow for more efficient combustion of fuel, which reduces emissions. High-volume combustion technologies are also being used to develop new types of thermal power plants that use renewable energy sources, such as biomass and solar thermal energy.

This steam is used to rotate the turbine blade turbine shaft is connected to the generator. The generator converts the kinetic energy of the turbine impeller into electric energy.

Understanding the Working of a Thermal Power Plant

Thermal power plant play a crucial role in meeting the energy demands of industries and households. These plants utilize the principles of thermodynamics to convert heat energy into electrical power efficiently. In this article, we will delve into the working of a thermal power plant, focusing on its key components and processes.

- Fuel Combustion:

- The process begins with the combustion of a fuel source, which can be coal, natural gas, or oil. This combustion generates high-temperature heat energy.

- Boiler System:

- The produced heat is transferred to a boiler, where water is converted into steam through a process known as steam generation.

- The steam produced in the boiler is under high pressure and temperature.

- Steam Turbine:

- The high-pressure steam is directed into a steam turbine. This turbine consists of multiple blades attached to a shaft.

- The steam’s high energy causes the turbine blades to spin rapidly.

- Mechanical Energy to Electrical Energy:

- As the turbine blades rotate, they transfer their mechanical energy to a generator.

- The generator converts this mechanical energy into electrical energy using electromagnetic induction principles.

- Cooling System:

- After passing through the turbine, the steam needs to be condensed back into water. This is achieved in the condenser.

- A cooling medium, often water, is used to condense the steam, and the resulting water is then pumped back into the boiler for reuse.

- Power Distribution:

- The generated electrical energy is now ready for distribution. Transformers are used to step up the voltage for efficient long-distance transmission.

- Grid Connection:

- The electricity is then fed into the power grid, from where it reaches homes, industries, and businesses.

Thermal power plant provide a reliable and consistent source of electricity by harnessing the heat energy from fuel combustion. Understanding their working is essential for ensuring the efficient generation and distribution of electrical power, making them a vital part of the energy landscape in India and Asia.

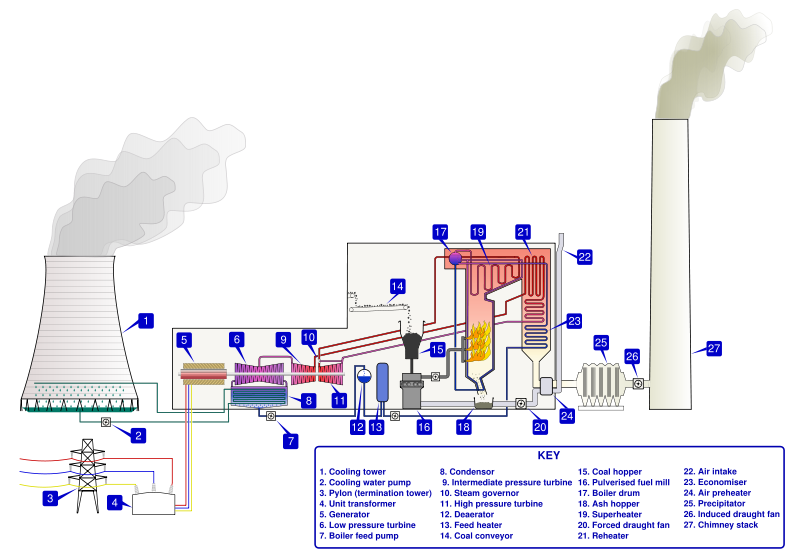

Layout and Working Principle Diagram of Thermal Power Plant

Thermal Power Plants Station and Thermodyne

Thermodyne Engineering Systems is a leading manufacturer of Industrial boilers and energy solutions. We have over 23 years of experience in the industry, and our products are used by businesses and organizations all over the world.

Our boilers are designed to generate high-pressure and-temperature steam, which is used to rotate turbines and generate electricity. We offer a wide range of boilers to meet the needs of our customers, including fire tube boilers, water tube boilers, and superheaters.

In addition to our boiler manufacturing capabilities, we also provide energy solutions to our customers. We help them assess their energy needs, design a system that meets their specific requirements. We install and maintain their equipment too.

Our goal is to help our customers save money on their energy costs. We offer a variety of energy-efficient products and services, and we work with our customers to develop customized solutions that meet their specific needs.

If you are looking for a reliable and experienced boiler manufacturer, or if you need help with your energy needs, contact Thermodyne Engineering Systems today. We would be happy to discuss your requirements and help you find the best solution for your business.

We also do turnkey steam industrial boiler plant projects including installation and commissioning of a boiler and its accessories.

Working Components of Thermal Power Plant

Thermal Power Plant consists of a whole set of steps in series for producing electricity.

Thermal power plant are a major source of electricity in the world. They generate electricity by burning fossil fuels, such as coal, natural gas, or oil. The heat from the combustion of these fuels is used to generate steam, which then drives a turbine to generate electricity.

The fuel for a thermal power plant is typically transported from mines to the plant’s fuel storage facility via trains. The fuel is then crushed into smaller pieces using crushers before being fed into the boiler furnace. Once inside the boiler, the fuel undergoes combustion, generating a substantial amount of heat. This heat is then transferred to water, which turns into steam. The steam is then used to drive a turbine, which is connected to a generator. The generator converts the mechanical energy of the turbine into electrical energy.

Thermal power plants are a reliable source of electricity, but they also have a number of environmental impacts. The combustion of fossil fuels releases pollutants into the atmosphere, such as sulfur dioxide, nitrogen oxides, and particulate matter. These pollutants can cause a number of health problems, such as asthma, bronchitis, and heart disease. Thermal power plants also contribute to climate change by emitting greenhouse gases, such as carbon dioxide.

Despite the environmental impacts, thermal power plants are still an important source of electricity. They are reliable and relatively inexpensive to operate. As the world’s population grows and energy demand increases, thermal power plants are likely to remain an important part of the global energy mix.

On the other hand treated water is free from impurities and the air is fed to the boiler drum where the combustion heat from the fuel is transferred to water to convert it into high-pressure and temperature steam.

Generally, flue gases from the boiler exhaust are at high temperature and if this heat is not utilized will lead to a large number of losses resulting in reduced boiler efficiencies.

So generally this waste heat is recovered by heating either air required for combustion or preheating water before sending it into a boiler.

Flue gases are then allowed to pass through a dust collector or a bag filter to arrest dust particles so as to prevent air pollution before sending it to the atmosphere through a chimney.

Water Treatment Plant of Thermal power Plant

In thermal power, plant water is used in large quantities this water is converted into steam and used to rotate the turbine so this water and steam come into direct contact with the boiler, boiler tubes, boiler accessories, and turbine blades.

Normal water is taken from the river, well contains a lot of dirt, suspended particulate matter (SPM), dissolved minerals, and dissolved gases such as air, etc. If the water fed to the boiler is not treated then it will reduce the life and efficiency of equipment by corroding the surfaces and scaling equipment which may lead to overheating of pressure parts and explosions.

Suspended matter from the water is removed by adding alum in the water tank through gravity separation. The addition of alum coagulates the suspended particles and due to an increase in the density, it settles at the bottom of the tank through gravity.

After gravity separation, water softening is done by the ion exchange process. As the hardness comes through the carbonates and bicarbonates of sodium and magnesium, these salts are removed from the water anion exchange and cation exchange process.

Water also contains dissolved oxygen and this leads to corrosion and fouling of boiler tubes and surfaces when it comes in their contact. So removing dissolved oxygen from water is done by adding oxygen scavengers and by using a Deaerator tank.

The deaerator tank also acts as a feed water tank to store the feed water. On heating feed water in a deaerator tank decreases the solubility of air in water, thereby removing the dissolved air from the water.

“Thermodyne supplies both Water Softeners and Deaerator tanks to improve the quality of feed water to the boiler as this improves the life and efficiency of your boiler and its equipment.”

Steam Boiler

A boiler is a pressure vessel that is used to generate high-pressure steam at a saturated temperature. At this high pressure and temperature generally, bi-drum water tube boilers are used.

Thermodyne Engineering Systems manufactures water tube boilers of various sizes and capacities that can run on various fuels.

Water-tube boiler consists of a furnace enclosed by the water tube membrane. The crushed fuel from the crushers is fed into the boiler furnace over the grate.

The hot air from the Forced Draft (FD) fan is mixed with the crushed fuel causing the combustion of fuel.

Combustion of fuel generates a lot of radiation heat which is transferred to water in the membrane tubes. Flue gases generated during combustion travel at high velocity across the convection bank of tubes thereby heating water through convection heat transfer. Hot water is sent into the boiler drum at high pressure through the feed-water pump.

Also Read: Combination Boilers

The boiler tubes which are in contact with low temperature acts as downcomers to circulate the water while the tubes which are in contact with high-temperature act as risers to carry steam.

This leads to an effective circulation of water thereby preventing the tubes from getting overheated.

The steam leaving the boiler is at a saturated temperature and pressure but there are a lot of heat losses during its transportation to the turbines.

So to increase the quality of the steam, a steam Superheater is installed in a radiate section of a boiler to increase its temperature and dryness fraction without increasing its pressure as well as to accommodate for the transportation temperature losses.

The exhaust gases leaving the boiler are generally at high temperatures and this waste heat is extracted by installing an Economiser or Water Preheater to preheat the feed water to the boiler and Air Preheaters to pre-heat the air coming from the Forced Draft Fan required for the combustion of fuel.

Installing this equipment helps to decrease the flue gas temperature thereby increasing the efficiency.

The flue gases leaving the boiler also contain some ash particles, so as to reduce air pollution, flue gases are allowed to pass through the Dust Collectors and Bag Filters to remove the ash particulates from the flue gases and are sometimes passed through the Wet Scrubbers to decrease the sulfur content from the gases.

The flue gases are drawn through this equipment using an Induced Draft (ID) Fan which is designed for a fixed capacity and head to prevent any backpressure. After the ID fan, flue gases are exhausted off into the atmosphere using a chimney.

What is Turbine

Other Components of Thermal Power Plant

Thermal Power Plants Resources

Thermal Power Plant Related FAQs

1. What is a thermal power plant?

A thermal power plant is a type of power plant that converts the heat energy released from burning fossil fuels into electrical energy. Thermal power plants are the most common type of power plant in the world.

2. How does a thermal power plant work?

Thermal power plants work using a thermodynamic process called the Rankine cycle. The Rankine cycle involves four main steps:

- Evaporation: Fuel is burned in a boiler to heat water and produce steam.

- Expansion: The steam is expanded through a turbine, which turns a generator to produce electricity.

- Condensation: The steam is then cooled and condensed back into water in a condenser.

- Pumping: The condensed water is pumped back into the boiler to start the process over again.

3. What are the main components of a thermal power plant?

The main components of a thermal power plant are:

- Boiler: The boiler heats water to produce steam.

- Turbine: The turbine expands the steam to produce mechanical energy.

- Generator: The generator converts the mechanical energy from the turbine into electrical energy.

- Condenser: The condenser cools and condenses the steam back into water.

- Cooling tower: The cooling tower transfers heat from the condenser to the atmosphere.

4. What types of fuels are used in thermal power plants?

The most common types of fuels used in thermal power plants are coal, oil, and natural gas. However, thermal power plants can also use other fuels, such as biomass and waste.

5. How efficient are thermal power plants?

The efficiency of a thermal power plant is the percentage of the heat energy from the fuel that is converted into electrical energy. The efficiency of thermal power plants has increased over time, and modern thermal power plants can have efficiencies of up to 40%.

6. What are the environmental impacts of thermal power plants?

Thermal power plants can have a number of environmental impacts, including:

- Air pollution: Thermal power plants emit air pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter. These pollutants can cause respiratory problems and other health problems.

- Water pollution: Thermal power plants use a lot of water for cooling, and this water can be polluted with chemicals and heavy metals.

- Greenhouse gas emissions: Thermal power plants emit greenhouse gases such as carbon dioxide, which contribute to climate change.

7. What are some of the challenges facing thermal power plants?

Thermal power plants face a number of challenges, including:

- Environmental regulations: Governments around the world are implementing increasingly strict environmental regulations on thermal power plants. This is making it more expensive and difficult to operate thermal power plants.

- Competition from renewable energy: Renewable energy sources, such as solar and wind power, are becoming increasingly competitive with thermal power plants. This is due to the decreasing cost of renewable energy technologies and the increasing availability of government subsidies for renewable energy.

- Public pressure: There is growing public pressure to reduce air pollution and greenhouse gas emissions. This is making it more difficult to build and operate new thermal power plants.

8. What are some of the ways to make thermal power plants more environmentally friendly?

There are a number of ways to make thermal power plants more environmentally friendly, including:

- Using cleaner fuels: Thermal power plants can switch to cleaner fuels, such as natural gas, instead of coal.

- Installing pollution control equipment: Thermal power plants can install pollution control equipment to reduce their emissions of air pollutants.

- Using more efficient technologies: Thermal power plants can use more efficient technologies to improve their efficiency and reduce their emissions.

- Co-firing with biomass: Thermal power plants can co-fire biomass with fossil fuels to reduce their emissions of greenhouse gases.

9. What is the future of thermal power plants?

The future of thermal power plants is uncertain. Thermal power plants will continue to play an important role in the global energy mix for the foreseeable future. However, the role of thermal power plants is likely to decline over time as renewable energy sources become more competitive.

10. What are some alternatives to thermal power plants?

Some of the alternatives to thermal power plants include:

- Renewable energy sources: Renewable energy sources, such as solar and wind power, are becoming increasingly competitive with thermal power.

- Nuclear power: Nuclear power plants produce electricity without emitting greenhouse gases, but they raise concerns about safety and waste disposal.

- Hydroelectric power: Hydroelectric power plants