What is Boilers Efficiency

Boiler efficiency is a measure of how well a boiler converts fuel into useful heat. It is calculated by dividing the useful heat output by the total energy input. Boiler efficiency is typically expressed as a percentage, and can range from as low as 50% to as high as 98%.

There are a number of factors that can affect boiler efficiency, including the type of fuel used, the , and the way it is operated. For example, boilers that use natural gas or propane tend to be more efficient than boilers that use oil or coal. Boilers with a high-efficiency design, such as condensing boilers, can also be more efficient than traditional boilers. Finally, proper operation of a boiler, such as keeping the combustion chamber clean and the water level correct, can also help to improve efficiency.

It is a recognized truth that the original cost of the boiler is a small part of the total costs associated with the boiler over its existence. In the working life of a boiler, the major price comes out of the fuel costs. This is why making sure the effective operation of the boiler is crucial to optimize the fuel costs.

Why is boiler efficiency important?

- Cost Savings: A highly efficient boiler can lead to significant savings in energy consumption, resulting in lower fuel costs and operational expenses. By extracting the maximum amount of heat from the fuel, an efficient boiler minimizes energy wastage, ultimately saving money for the industry.

- Environmental Impact: Energy efficiency is directly linked to reduced greenhouse gas emissions. Operating a more efficient boiler allows industries to contribute to environmental sustainability by minimizing their carbon footprint and overall impact on climate change.

- Resource Conservation: Improving boiler efficiency helps conserve natural resources. By using fuel more effectively, industries reduce the demand for fossil fuels, promoting sustainable energy practices and reducing reliance on finite energy sources.

- Enhanced Performance and Reliability: An efficient boiler not only maximizes energy utilization but also enhances overall performance. It ensures consistent and reliable steam or heat generation, supporting uninterrupted industrial processes and minimizing downtime.

- Compliance with Regulations: Many jurisdictions have established energy efficiency standards and regulations to promote sustainable practices and reduce environmental impact. Meeting or exceeding these regulations is crucial for industry compliance and avoiding potential penalties

The goal of the performance test is to define the actual production and efficiency of the boiler and compare it with design preferences or norms. It is a symbol for tracking day-to-day and season-to-season changes in boiler efficiency and power efficiency enhancements.

Boiler Efficiency Definition

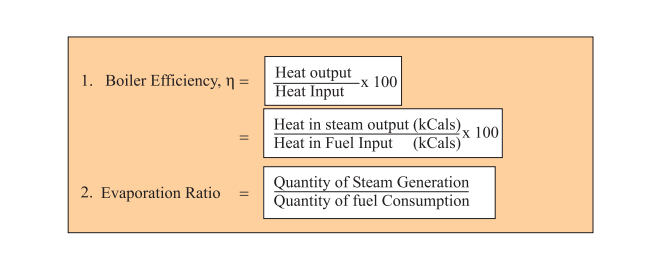

Boiler Efficiency Calculation Formula

Boiler efficiency (%) = [Q (H-h)/q*GCV]*100(heat exported by the fluid (Enthalpy of steam (Kcal/kg)– Enthalpy of water (kcal/kg) )/Gross calorific value of the fuel.) x 100.

Combustion

Combustion is the process of burning fuel to release heat. In a boiler, combustion takes place in the furnace. The fuel is mixed with air and ignited, and the heat released from the combustion process is used to heat the water or other fluid.

The efficiency of a boiler is affected by the completeness of the combustion process. If the combustion is incomplete, some of the fuel will not be burned completely, and this will result in heat losses.

There are a number of factors that can affect the completeness of the combustion process, including:

- The type of fuel used

- The amount of air available for combustion

- The temperature of the furnace

- The design of the boiler

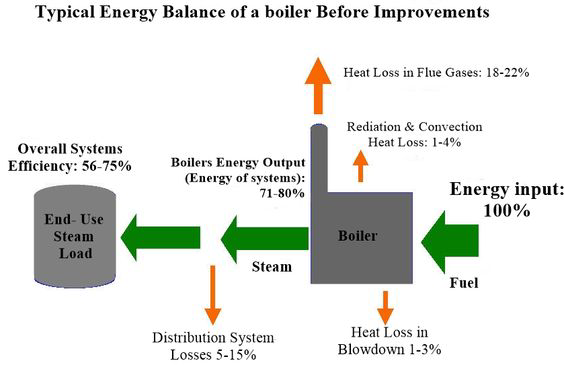

Steam Boiler Efficiency & Boiler Performance

Boiler heat loss is the loss of money, if your business losing money then it is a serious concern. An efficient boiler is a solution. Thermodyne Engineering Systems provide you with various ways to improve your boiler efficiency, but to understand these ways we must know where the heat losses are actually occurring in your boiler system.

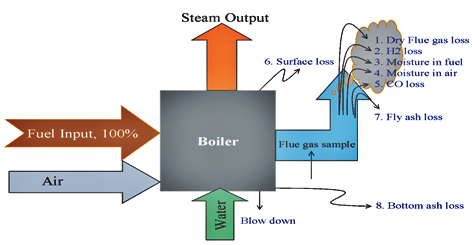

Boiler Efficiency Diagram

All the heat losses cannot be fully recovered but they can be reduced to a large amount thereby improving your steam boiler efficiency which will save you a lot of money.

Efficiency of Boiler & Heat Losses Diagram

There is various type of heat losses in the boiler.

Some of them are:-

Heat Loss Due to Unburnt Carbon

During the combustion process, most of the fuel gets burnt but some of the fuel particles remain unburnt and are deposited along with the ash.

If the size of fuel particles fed to the furnace is large, the surface area of contact with air and fuel particles decreases and the quantity of unburnt increases. This accounts for potential fuel losses which would otherwise have been burnt to generate heat.

Dry Flue Gas Losses

This account for major heat losses amongst all. If the flue gases leaving the boiler is at a high temperature than the temperature for which it is designed, then most of the heat is getting wasted leading to reduced boiler efficiency.

Heat Loss Due to Moisture in Fuel

If the fuel which is fed to furnace for combustion has a very high moisture content, most of the ignition heat required to burn the fuel will be wasted to evaporate the moisture content and then it will burn the fuel.

Heat Loss Due to Radiation and Convection

These losses cannot be measured but they increase with an increase in boiler surface temperature.

Loss due to sensible heat in bottom ash

Ash which is formed after the fuel is burnt, is generally at a high temperature. No utilization of this heat will lead to significant heat losses.

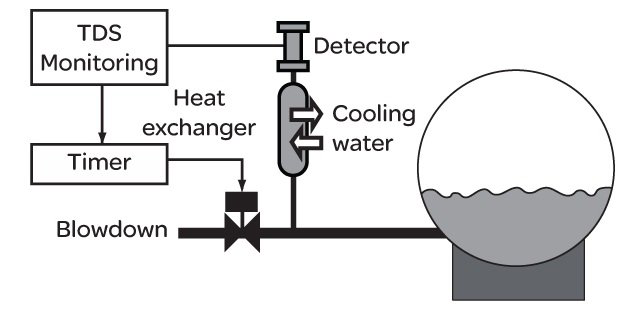

Blowdown Losses

Blowdown of impurities deposited at the bottom of the shell is considered a necessary activity because these impurities absorb heat. So in order to remove these impurities some amount of water is released from the shell which also leads to heat losses.

Boiler Efficiency Improvement Steps:

After Analyzing heat losses in industrial boilers, boiler engineers or technicians can help you to increase your boiler efficiency by 6% – 10%.

Here are the few boiler efficiencies boosting steps listed below:

- Complete combustion of fuel so that no unburnt is left behind is a good practice and will add to the boiler efficiency.

- Unburnt carbon coming out of the furnace can be re-injected again into the furnace so that complete combustion of fuel can take place.

- Bottom ash from the boiler is generally at a high temperature and has a lot of sensible heat. This heat can be utilized to preheat the air or water used in a boiler.

- The optimum ratio of fuel to air and keeping the excess air as low as possible keeping in mind the complete combustion of fuel can increase the furnace temperature thereby increasing the radiation heat. Reducing excess air by 5% can increase boiler efficiency by 1%.

- Moisture free fuel should be fed to the boiler so that no amount of heat is lost in removing the moisture from fuel and all the heat can be efficiently used to convert water to steam.

- Most heat losses are due to the high temperature of dry flue gases leaving the boiler. Boiler maintenance should be done regularly and be removing the scale deposited on the heat transfer tubes should be given prime importance as this scale prevents the transfer of heat between flue gas and water.

- Continuous blowdown of water is necessary to keep water impurities to optimum level but this also lead to heat losses, so in order to reduce the heat losses, it is important to check the number of blowdowns to be done in a day as well as this heat from water can be recovered by installing blowdown heat recovery system for preheating water or air entering a boiler.

- Radiation and convection losses though cannot be measured but can be reduced by regular maintenance of boiler and using insulation to prevent heat losses to the surrounding.

- Steam which is used in a process after transferring its heat gets converted to condensate water. This condensate is generally at high temperature and can be recovered using Condensate Recovery Module which can be reused to preheat water or air.

Other ways of improving your boiler efficiency are by installing Waste Heat recovery boilers/devices. Heat from the flue gases leaving the boiler can be recovered using equipment such as Economisers, Air pre-heaters, superheaters or using this waste heat in your process.

Boiler Efficiency Improvement Services in India

Thermodyne Engineering System has 23 years of experience in the design and fabrication of this equipment and can provide you with numerous solutions of recovering your waste heat from the boiler.

Contact our boiler engineering to boost your boiler’s efficiency and save money.

The Efficiency of Boiler-Related FAQs

Boiler efficiency is a measure of how well a boiler converts fuel into heat. It is expressed as a percentage, with 100% being the most efficient.

Boiler efficiency is calculated by dividing the useful heat output by the heat input. The formula is:

Efficiency = (Useful heat output / Heat input) x 100

The factors that affect boiler efficiency include the type of boiler, the age of the boiler, the fuel used, the maintenance of the boiler, and the environment in which the boiler is used.

The average boiler efficiency in the United States is about 80%. However, there are many high-efficiency boilers available that can achieve efficiencies of up to 98%

There are a number of things you can do to improve the efficiency of your boiler, including:

Regularly maintain your boiler.

Use the correct fuel for your boiler.

Insulate your boiler and pipes.

Install a condensing boiler.

There are a number of benefits to having a high-efficiency boiler, including:

Lower energy bills.

Reduced emissions.

Longer boiler lifespan.

The cost of installing a high-efficiency boiler will vary depending on the type of boiler, the size of the boiler, and the location of the boiler. However, in general, high-efficiency boilers are more expensive to install than traditional boilers.

The amount of time it takes to recoup the cost of a high-efficiency boiler will vary depending on the cost of the boiler, the energy savings, and the cost of energy. However, in general, high-efficiency boilers can save you money on your energy bills in a relatively short period of time.

There are a number of different types of high-efficiency boilers available, including:

Condensing boilers.

Biomass boilers.

Solar thermal boilers.

High-efficiency boilers have a number of safety features, including:

Flame failure safety devices.

Pressure relief valves.

Temperature sensors.