Textile

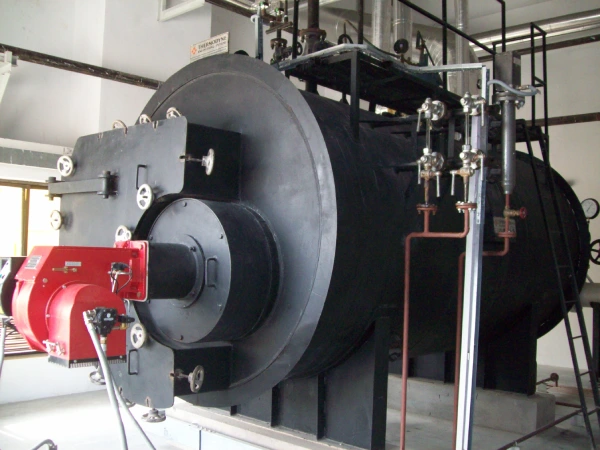

Application of steam boilers in Textile industry

- Boilers generate the high-pressure steam needed in the dyeing process to ensure dyes penetrate fabric fibers effectively, producing vibrant, lasting colors. The steam helps maintain consistent temperatures and pressure levels, enabling quality and uniformity in fabric dyeing and finishing.

- Boilers supply controlled heat necessary for drying, wrinkle removal, and texture setting in fabrics. By providing the consistent heat required in finishing processes, boilers help maintain fabric smoothness and quality, delivering the durability and appearance textile manufacturers strive for.

- In weaving and spinning departments, maintaining appropriate humidity is crucial to prevent fiber damage. Boilers are used to produce steam that helps regulate humidity, keeping fibers flexible and preventing breakage. This steam-based moisture control improves production efficiency and fabric quality.

For fabric printing, boilers provide the stable steam essential for maintaining consistent temperatures, which is necessary for setting dyes and achieving uniform, vivid prints. This stability ensures that fabrics retain color vibrancy and quality, making boilers a key component in high-quality textile printing.

- Heat setting stabilizes the dimensions of synthetic fabrics, making them resistant to wrinkling and shrinkage. Boilers generate the high-temperature steam required for this process, helping fabrics retain their shape and finish during and after production.

- Boilers supply the steam needed for scouring, a cleaning process that removes natural impurities from fibers before dyeing. This high-temperature steam helps achieve thorough cleaning, ensuring the purity of fabrics and enhancing their readiness for subsequent processes.

Textile

- Boilers generate the high-pressure steam needed in the dyeing process to ensure dyes penetrate fabric fibers effectively, producing vibrant, lasting colors. The steam helps maintain consistent temperatures and pressure levels, enabling quality and uniformity in fabric dyeing and finishing.

- Boilers supply controlled heat necessary for drying, wrinkle removal, and texture setting in fabrics. By providing the consistent heat required in finishing processes, boilers help maintain fabric smoothness and quality, delivering the durability and appearance textile manufacturers strive for.

Humidification

- In weaving and spinning departments, maintaining appropriate humidity is crucial to prevent fiber damage. Boilers are used to produce steam that helps regulate humidity, keeping fibers flexible and preventing breakage. This steam-based moisture control improves production efficiency and fabric quality.

For fabric printing, boilers provide the stable steam essential for maintaining consistent temperatures, which is necessary for setting dyes and achieving uniform, vivid prints. This stability ensures that fabrics retain color vibrancy and quality, making boilers a key component in high-quality textile printing.

- Heat setting stabilizes the dimensions of synthetic fabrics, making them resistant to wrinkling and shrinkage. Boilers generate the high-temperature steam required for this process, helping fabrics retain their shape and finish during and after production.

- Boilers supply the steam needed for scouring, a cleaning process that removes natural impurities from fibers before dyeing. This high-temperature steam helps achieve thorough cleaning, ensuring the purity of fabrics and enhancing their readiness for subsequent processes.

Revosteam

100 kg/hr – 900 kg/hr

Savemax

1 TPH to 20 TPH

Intech

500 kg/hr – 6000 kg/hr

Combitherm

1 TPH to 20 TPH

Combitherm Ultra

1 TPH to 10 TPH

Electra

55 Kg/hr to 2000 Kg/hr

Fluidtherm

1 lac Kcal/hr to 60 Lac Kcal/hr