Limit Switch: Essential for Boiler Control and Safety

The role of limit switch in boilers control and safety

Steam Boiler is an important equipment in many industries, providing heat and energy. To ensure the safe and efficient operation of Industrial steam boilers, it is important to have a limit switch.

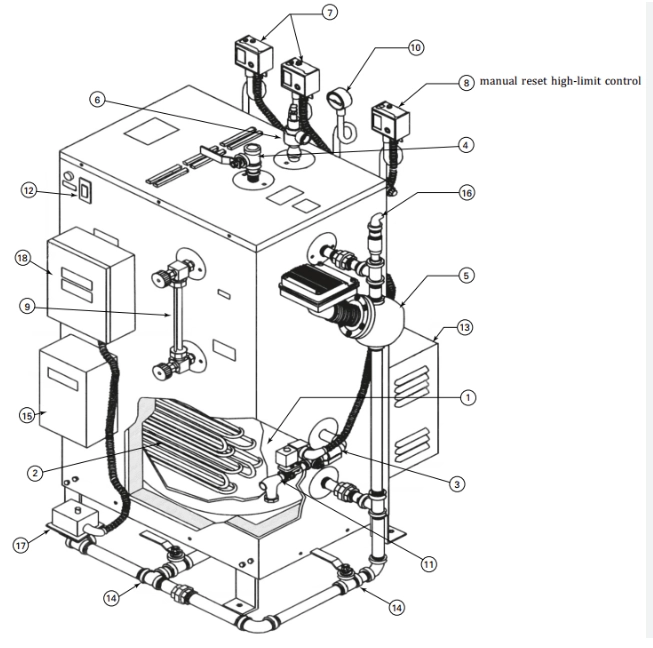

The limit switch is the main control device for a Industrial boiler. It monitors and controls key parameters such as temperature, pressure, flow rate, and flame stability. If these parameters exceed safe limits, the limit switch will trigger necessary actions to prevent accidents, equipment damage, or inefficient operations.

For example, if the temperature of the boiler water exceeds a safe limit, the limit switch will shut down the boiler to prevent the water from boiling over. If the pressure of the boiler water exceeds a safe limit, the limit switch will open a valve to release the excess pressure. And if the flow rate of the boiler water falls below a safe limit, the limit switch will turn on a pump to increase the flow rate.

Steam Boiler Limit Switches: An Overview

Limit switches play a critical role in boiler systems as they act as safety devices to prevent potential hazards. These switches are designed to monitor and control the temperature, pressure, and other parameters within the boiler. By doing so, they ensure that the boiler operates within safe limits and protects against overheating, excessive pressure, and other potentially dangerous conditions.

The Function of Limit Switches Industrial Steam Boiler

Limit switches act as sensors or control devices that detect specific conditions or limits within the boiler system. Once a predefined threshold is reached or exceeded, the limit switch triggers an action to either shut down the boiler or activate a safety mechanism to prevent any potential damage or accidents.

Types of Limit Switches boiler

There are various types of limit switches used in boiler systems, each serving a specific purpose. Let’s explore some common types:

1. Temperature Limit Switches

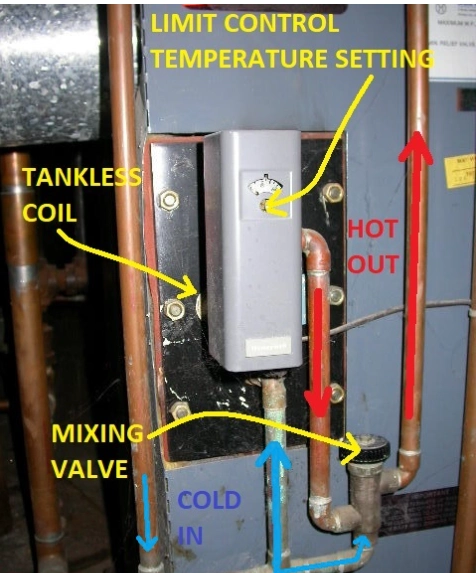

Temperature limit switches are designed to monitor and control the temperature levels within the boiler. When the temperature rises above a predetermined set point, the limit switch triggers a response to prevent overheating. This response could include shutting down the burner or activating a cooling mechanism.

2. Pressure Limit Switches

Pressure limit switches are responsible for monitoring the pressure levels inside the boiler. If the pressure exceeds the safe operating range, the limit switch takes immediate action to prevent damage. This action could involve shutting off the fuel supply or activating a pressure relief valve.

3. Flow Limit Switches

Flow limit switches are used to detect the flow rate of water or other fluids within the boiler system. They ensure that there is a sufficient flow to prevent overheating while also preventing excessive flow rates that could lead to issues such as water hammer. When the flow rate falls below or exceeds the desired range, the limit switch triggers a response to maintain optimal conditions.

4. Flame Limit Switches

Flame limit switches are crucial for ensuring safe combustion within the boiler. They monitor the presence of a flame and detect any abnormalities or malfunctions. If the flame goes out or becomes unstable, the limit switch will shut down the burner and prevent the release of unburned fuel or gas.

Importance of Limit Switches in Boiler Systems

Limit switches serve as the main control for boilers due to their crucial role in maintaining safe and efficient operations. Here are some key reasons why limit switches are of utmost importance:

- Safety: Limit switches act as a vital safety measure by preventing potential hazards, such as overheating, excessive pressure, or flame failure. They help protect both the boiler system and the surrounding environment.

- Efficiency: By monitoring and controlling key parameters, limit switches optimize the boiler’s performance and energy consumption. They ensure that the boiler operates within the desired range, leading to improved efficiency and reduced operational costs.

- Equipment Protection: Limit switches help safeguard the boiler and its components from damage caused by extreme conditions. By shutting down the system or triggering safety mechanisms, they prevent costly repairs and extend the lifespan of the equipment.

- Compliance: Many regulatory bodies and safety standards require the use of limit switches in boiler systems. By incorporating limit switches, users can ensure compliance with industry regulations and standards.

FAQs about Limit Switches in Boiler Systems

- Here are some frequently asked questions about limit switches and their role as the main control for boilers:

The primary purpose of a limit switch in a boiler is to ensure safety. It monitors and controls key parameters such as temperature, pressure, flow rate, and flame stability. When these parameters exceed safe limits, the limit switch triggers actions to prevent accidents, equipment damage, or inefficient operations.

limit switch works by continuously monitoring the conditions within the Steam boiler. It is connected to a control system that receives input from the limit switch. When a specific threshold or limit is reached, the limit switch sends a signal to the control system, which then initiates the necessary actions, such as shutting down the boiler or activating safety mechanisms.

Yes, a properly functioning limit switch can help prevent Industrial steam boiler explosions. By monitoring parameters such as temperature and pressure, the limit switch ensures that the boiler operates within safe limits. If these limits are exceeded, the limit switch triggers actions to mitigate the risks and prevent catastrophic failures.

In many countries, limit switches are a legal requirement for boilers. Regulatory bodies and safety standards enforce the use of limit switches to ensure the safe operation of boiler systems. It is essential to comply with these regulations and standards to protect lives, property, and the environment.

Limit switches should be regularly inspected and maintained as part of routine boiler maintenance. The frequency of inspections may vary depending on the specific boiler and its operating conditions. It is recommended to follow the manufacturer’s guidelines and consult with a qualified professional to determine the appropriate inspection and maintenance schedule.

Like any mechanical or electrical component, limit switches can fail or malfunction over time. Factors such as wear and tear, environmental conditions, and improper maintenance can contribute to their failure. Regular inspections, testing, and prompt replacement of faulty limit switches are necessary to ensure their reliable operation.

Limit switches are undoubtedly the main control for boilers, playing a critical role in maintaining safe and efficient operations. They act as the guardians of the boiler system, monitoring and controlling key parameters to prevent accidents, protect equipment, and optimize performance. By understanding the function and importance of limit switches, users can ensure the reliability, safety, and longevity of their boiler systems.

Limit Switch is the main control for the boiler. This control will be set for the desired water temperature or steam pressure of the system. Their compact design and easy connections.