Thermodyne Engineering Systems

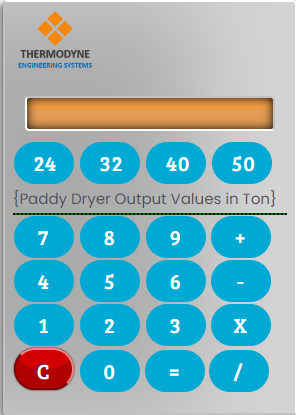

Ricemill Boiler Calculator

Ricemill Boiler Calculator Manual

To determine the boiler requirements for your paddy dryer, follow these steps:

Input the capacity of your paddy dryer in tons. For example, if you a 24-ton paddy dryer, enter 24.

The calculator will provide you with the recommended boiler capacity in tons. For a 24-ton paddy dryer, the recommended boiler capacity is 2 tons.

Using the Calculator:

Our Rice Mill Boiler Calculator is a user-friendly tool designed to simplify the process of determining your boiler needs. Simply input your paddy dryer capacity, and it will provide you with the required boiler capacity.

Paddy Dryer Capacity Reference:

24 Ton

32 Ton

40 Ton

50 Ton

This is approximate calculation for exact calculation you can contact our sale person.

For Free Consultation

please call us at +91 9990226006

Rice Mill Steam Boiler Manufacturer

The steam boiler is the main equipment in the Rice mill industry. High-pressure & high-temperature are needed throughout the process of rice milling. Rice milling requires a combination of high pressure and high temperature throughout the various stages of the process.

Boilers in Rice Mills

Boilers are an essential part of the rice milling industry, whether you know it or not. If you’re talking about Parboiled Rice, Steamed Rice, Paddy Drying, or other Rice milling processes, much of the manufacturing process involves the use of steam or hot water created by industrial boilers. As a result, selecting a boiler system for a Rice Mill should be done with caution. Let’s take a closer look at how steam boilers lead to Rice milling’s performance.

Rice mill is one of the most important industries in India. Rice industry is consuming energy in a very high amount, so there is a need for a highly efficient steam processing boiler.

In the rice milling process, at the stage of rice cleaning, rice mills produce rice husk. Rice husk is the outermost layer of the wheat. So husk is available in a very big quantity in rice mills. It’s convenient to use rice husk as boiler fuel in the Rice milling process.

some of the advantages of using rice husk as boiler fuel in the rice milling process:

- Abundant and cost-effective fuel source: Rice husk is a by-product of the rice milling process, and it is abundant and relatively inexpensive. This makes it a cost-effective fuel source for rice mills.

- Reduces waste and promotes sustainability: Burning rice husk as fuel helps to reduce waste and promote sustainable practices in the rice milling industry. Rice husks are typically burned as waste, but using them as fuel can help to reduce the amount of waste that is produced.

- High calorific value: Rice husk has a high calorific value, which means that it produces a lot of heat when it is burned. This makes it an efficient and reliable energy source for powering boilers.

- Reduces environmental impact: Using rice husk as boiler fuel helps to reduce the environmental impact of rice milling. Rice husks produce less greenhouse gas emissions than fossil fuels, and they also produce less air pollution.

Overall, using rice husk as boiler fuel in the rice milling process offers a number of advantages. It is a cost-effective, sustainable, and efficient fuel source that can help to reduce the environmental impact of rice milling.

Rice Mill Steam Boiler Selection Factors

Rice milling process needs steam at a large amount to get things done in rice production. So we can say, steam boiler is an important machinery, used in the production of rice.

steam boilers are an important machinery used in the production of rice. Steam is used in a variety of rice milling processes, including:

- Paddy drying: Steam is used to dry paddy before it is milled. This helps to remove moisture from the paddy, which makes it easier to mill.

- Parboiling: Parboiling is a process that involves soaking paddy in water and then steaming it. This helps to improve the nutritional value of the rice and make it easier to digest.

- Milling: Steam is used to power the machinery that mills the paddy into rice. This includes the machines that remove the husk, bran, and germ from the paddy.

- Grading: Steam is used to heat the rice after it has been milled. This helps to remove any remaining moisture from the rice and make it easier to grade.

- Packing: Steam is used to heat the rice before it is packed. This helps to prevent the rice from spoiling.

In addition to these processes, steam boilers are also used to provide heat for other machinery in a rice mill, such as the dryers, conveyors, and elevators. Steam boilers are an essential part of the rice milling process, and they help to ensure that the rice is produced efficiently and safely.

Here are some of the benefits of using steam boilers in the rice milling process:

- Efficiency: Steam boilers are a very efficient way to generate heat. This can help to reduce the cost of energy and improve the profitability of the rice milling process.

- Safety: Steam boilers are a safe way to generate heat. They are equipped with safety features that help to prevent accidents and injuries.

- Environmentally friendly: Steam boilers can be fueled with a variety of renewable energy sources, such as biomass and solar energy. This can help to reduce the environmental impact of the rice milling process.

So let’s discuss some important factors to keep in mind while choosing a steam process boilers in your rice mill plant.

- Analyze the Needed Capacity of Steam Boiler: The boiler capacity must be based on the heating load including the heat losses in boiler or pipelines.

- Figure out the boiler heating parameters (Pressure, Temperature etc.)

- Decide the Steam Boiler Efficiency: For economical benefits, the boilers must have high thermal efficiency, the boiler output, quantity

- It is better to choose the Steam Boilers with the required capacity and combustion equipment based on proper calculations.

- The design of the boiler should be efficient and as per the need of the industry.

Rice Mill Boiler Machine Fuel

- Rice husk

- Coal

- Lignite

- Wood

- Bagasse

- Groundnut shells

- Petcoke, and several other Solid fuels

- Rice Mill Industry

Rice Mill Steam Boilers by Thermodyne Boilers

1. Combi Boiler (Ultra Model)

Our Combitherm Ultra Boilers (Combi Ultra Boiler) are factory assembled models.

- Our Combi boilers need very less site work and less service costs. So It’s the right fit for your rice milling business.

- This unique and compact design can handle almost all types of fuels such as wood, coal, briquettes, rice husk, pet coke, etc.

- Know about Combitherm’s Design and Specifications

- Multi-fuel choices Total flexibility.

- Husking to remove paddy husk from paddy kernel.

- Available in both manual and automatic fuel feeding systems.

- Easy installation & Low maintenance.

- Easy access for cleaning and inspection.

Buy Combitherm Ultra Boiler for your Rice Mill Business

2. Combitherm-Three Pass Smoke Cum Water Tube Type Boiler

Combitherm boiler or is known among others as the Combi boiler is a unique water cum smoke tube type design.

It is the mixture of both Water Tube Boiler and Smoke Tube Boiler where some tubes form the enclosed part of the external furnace in which water flows and rest of the tubes are placed in a shell in which flue gases flow.

- Combitherm (Combi Boiler) is a 2 pass design to increase the residence time and at the same time keeping the velocity optimum to achieve high convective heat transfer.

- 3 Pass Smoke Cum Water Tube Boiler design can burn a variety of fuels like Coal, Lignite, Rice Husk, Wood, Bagasse, and several other fuels.

- Can be converted to liquid/gaseous fuels as well.

Buy Combitherm Three Pass Boiler for your Rice Mill Business

Boilers in Rice Mills FAQ

A boiler is a device that produces steam by heating water. Steam is used in a variety of industries, including rice milling.

Boiler generates steam that is used in various rice milling processes such as parboiling, drying, and polishing. Steam is also used to power machinery in the rice mill.

There are two main types of boilers used in rice mills: fire-tube boilers and water-tube boilers. Fire-tube boilers have a firebox that heats tubes filled with water. Water-tube boilers have water tubes that pass through a firebox.

The capacity of the boiler, the type of fuel used, and the cost of the boiler are all important factors to consider when choosing a boiler for a rice mill.

Boiler provides a reliable source of heat for rice milling processes. Boiler also helps to reduce the amount of time required to process rice.

Boiler can be a fire hazard if not properly maintained. Boiler can also release harmful emissions into the air.

Boiler should be inspected and cleaned regularly. Boiler should also be serviced by a qualified technician on a regular basis.

Boiler should be operated by trained personnel. Boiler should be kept in a well-ventilated area. Boiler should not be overloaded.

Boiler must comply with environmental regulations that apply to the type of fuel used and the emissions produced.

More information about boilers used in rice mills can be found from boiler manufacturers, rice mill associations, and government agencies.

Boiler Resources Page Links Here

- Boiler Losses That Eat Away Your Profits

- Dissolved Gases in Feed Water and Its Effect

- Pressure Reduction System

- How to minimize the Blowdown Losses