IBR Steam Boiler

Thermodyne Engineering System is a leading manufacturer of IBR (Indian Boiler Regulation). Our company specializes in producing these specialized boilers, which adhere to the stringent standards set by the Indian Boiler Regulations. IBR Steam Boilers from Thermodyne Engineering System are known for their reliability, performance, and compliance with safety guidelines.

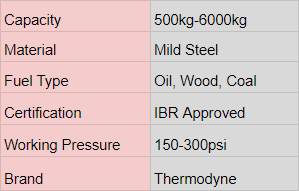

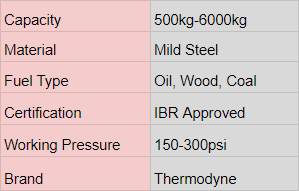

1 TPH IBR Steam Boiler, IBR Approved

We are recognized as a prominent manufacturer, supplier, and trader of High-Pressure Steam Boilers that deliver exceptional performance. These boilers are specially designed to produce steam at pressures exceeding 80 bar. They achieve this by utilizing a multitude of small-diameter tubes and ensuring water circulation through forced means. The various parts and components are meticulously designed and produced in our integrated facilities to ensure maximum heat transfer efficiency. Additionally, our valued clients can acquire these extremely durable boilers at an affordable price.

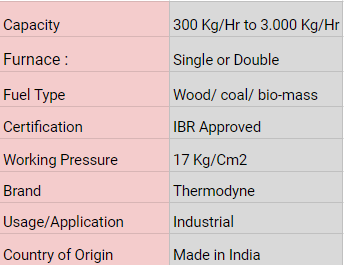

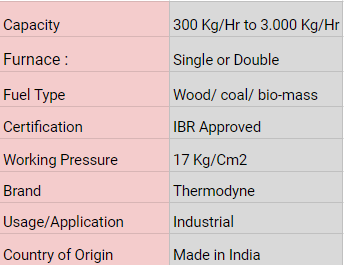

Wood or Coal Fired IBR Steam Boiler

Our Wood or Coal Fired IBR Steam Boilers are designed to prioritize safety, efficiency, reliability, and quiet operation. We engineer them for the utmost performance and dependable functionality.

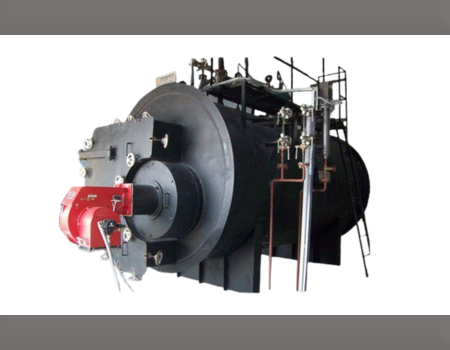

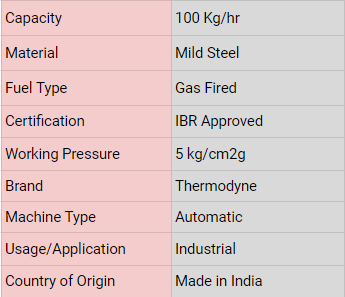

Gas Fired 100 Kg/hr IBR Steam Boiler

Applications:

Industrial applications like Dyes, Drugs & Pharmaceuticals, Chemicals, Food Industry, Paper & Plywood, Agro based Industries, Rubber Industry and other process industries.

Advantages:

- Fully Automatic unit

- Unique four pass design

- High efficiency and low running cost

- Minimum site-work, low installation costs

- Instant steaming within 5 minutes of cold start

- Built-in economiser increases the operating efficiency

- Fail-safe design and dependable operating instruments

Wood Fired IBR Steam Boiler

Combustion of fuel takes place inside a furnace where most of the radiation heat transfer occurs between flue gases and water while convective heat transfer dominates when flue gases are traveling at high velocity inside the tubes.

Applications:

Industrial applications like Dyes, Drugs & Pharmaceuticals, Chemicals, Food Industry, Paper & Plywood, Agro based Industries, Rubber Industry and other process industries.

Wood Fired 200 Kg/hr IBR Steam Boiler

Combustion of fuel takes place inside a furnace where most of the radiation heat transfer occurs between flue gases and water while convective heat transfer dominates when flue gases are traveling at high velocity inside the tubes.

Applications:

Industrial applications like Dyes, Drugs & Pharmaceuticals, Chemicals, Food Industry, Paper & Plywood, Agro based Industries, Rubber Industry and other process industries.

Gas Fired 500 Kg/hr Non-IBR Steam Boiler

Applications:

Industrial applications like Dyes, Drugs & Pharmaceuticals, Chemicals, Food Industry, Paper & Plywood, Agro based Industries, Rubber Industry and other process industries.

Advantages:

Fully Automatic unit

Unique four pass design

High efficiency and low running cost

Minimum site-work, low installation costs

Instant steaming within 5 minutes of cold start

Built-in economiser increases the operating efficiency

Fail-safe design and dependable operating instruments

An IBR steam boiler is a closed vessel that generates steam under pressure and is certified by the Indian Boiler Regulations (IBR). IBR boilers are used in a wide variety of applications, including power generation, industrial processes, and space heating.

IBR boilers are subject to stricter safety standards than non-IBR boilers. This is because IBR boilers are typically used in applications where there is a higher risk of explosion or other hazards.

IBR stands for Indian Boiler Regulations.

IBR steam boilers are safer and more efficient than non-IBR boilers. They are also more reliable and have a longer lifespan.

There are many leading IBR boiler manufacturers in India, including Thermodyne Engineering Systems, Agni Boilers Private Limited, and Hitech Technochem.

When choosing an IBR boiler manufacturer, you should consider the following factors:

- Experience: The manufacturer should have a proven track record of designing and manufacturing IBR boilers.

- Quality: The manufacturer should use high-quality materials and components.

- Safety: The manufacturer should have a strong commitment to safety.

- Service: The manufacturer should provide prompt and reliable service.

Wood-fired steam boilers are a renewable and environmentally friendly source of steam. They are also relatively inexpensive to operate.

A variety of types of wood can be used in a wood-fired steam boiler, including softwoods, hardwoods, and wood waste.

Wood-fired steam boilers emit some pollutants, such as particulate matter and carbon monoxide. However, these emissions are typically lower than the emissions from fossil fuel-fired boilers.

The cost of an IBR steam boiler will vary depending on the size, type, and features of the boiler. However, you can expect to pay anywhere from ₹5,00,000 to ₹20,00,000 for an IBR steam boiler.