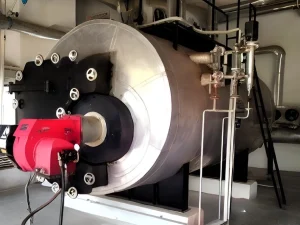

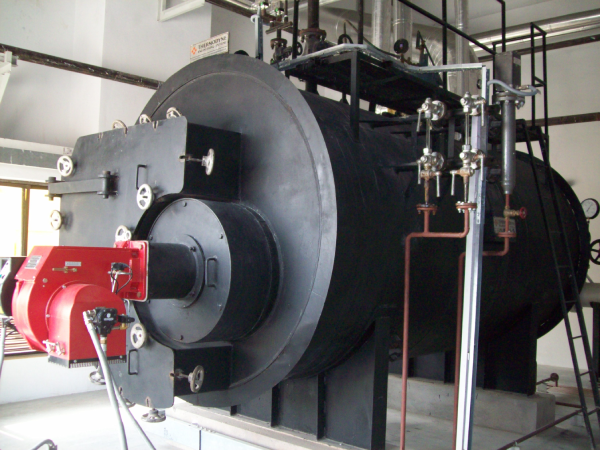

Oil & Gas Fired Boiler (Savemax) – Engineered for Superior Efficiency, Reliability & Industrial Performance

Oil & Gas Fired Boiler -Savemax

The Savemax is a three-pass, smoke-tube design, oil or gas fired boiler with an internal water-cooled furnace. This design ensures high efficiency and optimal performance, making it the ideal choice for various industrial applications.

Featuring a standard three-pass internal furnace smoke tube configuration with water enclosed reversal chamber. This design ensures enhanced heat transfer as the reversal chamber and the furnace are surrounded by water on all sides, making effective heat transfer of the flue gases to the water. The flue gases travel through the tubes in the 2nd and 3rd passes, delivering maximum heat to the water thereby producing steam efficiently.

- 1 TPH- 20 TPH

- Light oil

- Heavy oil

- PNG

- LPG

- Biogas

- Oil fired

- Gas fired

- Dual fuel fired (Oil cum gas)

- Pharmaceuticals

- Textiles

- Food processing

- Chemicals

- Rubber

- Dairy

- Beverages and others

Suggested Products

Wastetherm- (Waste Heat Recovery Boiler)

Steam Accumulator

Book a free Consultation

Related Blogs

Oil & Gas fired boiler related FAQ's

A gas fired boiler is a type of boiler that uses natural gas or LPG to produce steam or hot water for heating or industrial processes.

Thermodyne gas fired boilers are designed for maximum efficiency, delivering optimal heat transfer and minimal fuel consumption, making them ideal for energy-saving industrial applications.

An oil fired boiler uses heating oil as fuel to produce steam or hot water for processing and heating applications.

A gas fired boiler works by igniting gas fuel to heat water in tubes or a tank, converting it into steam for industrial or commercial applications.

It burns oil in a combustion chamber to heat water or generate steam, typically for industrial steam generation.

Gas boilers are cleaner and more efficient, but oil boilers may be preferred in areas with fuel limitations.

High efficiency, clean combustion, low maintenance, fast steam generation, and compact design.

Used in food processing, chemical, pharmaceutical, textiles, and packaging sectors.

Costs vary by size and capacity. Industrial models range from ₹10 lakh to ₹2 Cr.

The working principle involves burning oil to heat water within a three-pass heat exchanger design, maximizing energy transfer.

Contact us for more details about our boilers, installations and services.