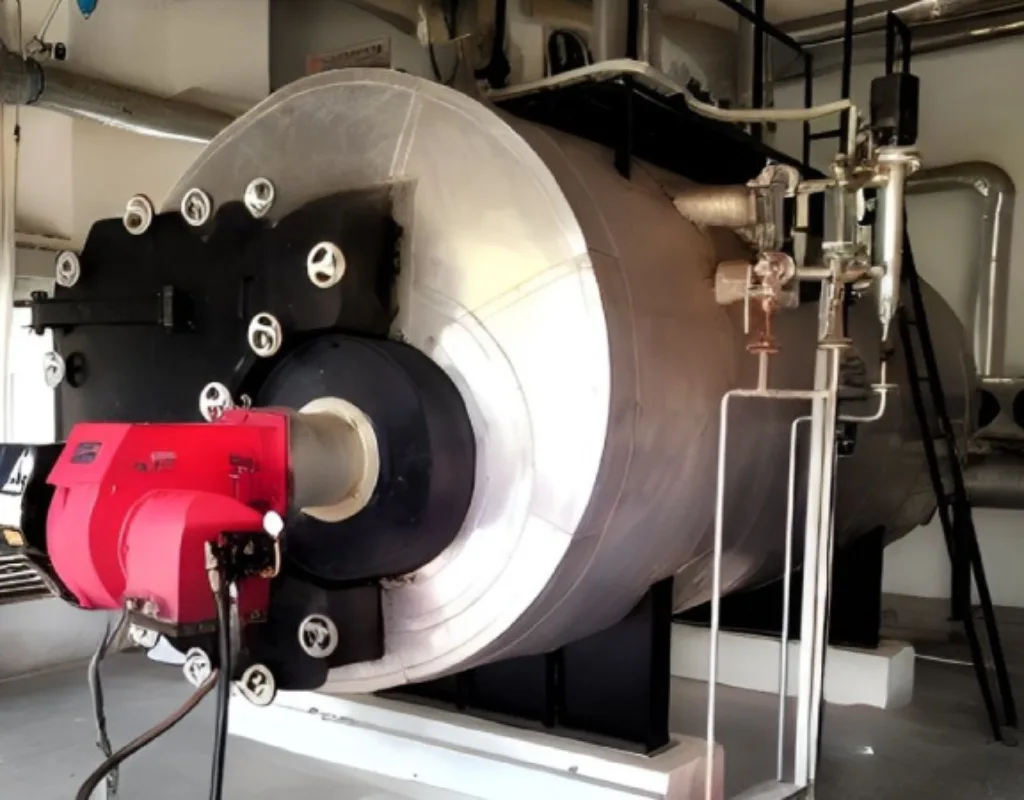

What is Fire Tube Boiler

A fire-tube boiler is a type of boiler in which the water or other fluid to be heated flows through tubes that are surrounded by fire. This is in contrast to a water tube boiler, in which the fire flows through tubes that are surrounded by water. Fire-tube boilers are typically used for smaller applications, such as heating homes or businesses, while water-tube boilers are used for larger applications, such as generating steam for power plants.

There are two main types of firetube boilers: horizontal fire-tube boilers and vertical firetube boilers. Horizontal firetube boilers are the most common type and are typically used for residential and commercial applications. Vertical fire-tube boilers are less common but are used in some industrial applications.

Fire Tube boiler is the simplest form of the internal furnace, a vertical fire tube boiler. Fire tube boilers are a portable boiler and it requires a small floor space. Fire Tube boilers are known for their compact design and efficient heat transfer capabilities, making them an ideal choice for applications where space is limited. Additionally, their portable nature allows for easy installation and relocation, making them versatile in various settings.

What is the working principle of the fire tube boiler?

The working principle of a fire tube boiler is relatively straightforward. In a fire tube boiler, hot gases pass through a series of tubes that are immersed in water within the boiler shell. The heat from the gases is transferred through the walls of the tubes to the water, creating steam.

Here are the key steps in the working principle:

- Fuel Combustion: The boiler is fueled, typically with coal, wood, or oil. The fuel undergoes combustion in the furnace, generating hot gases.

- Gases Flow Through Tubes: The hot gases produced during combustion travel through the tubes that are submerged in water.

- Heat Transfer: As the hot gases move through the tubes, heat is transferred from the gases to the water surrounding the tubes. This heat transfer raises the temperature of the water and converts it into steam.

- Steam Generation: The steam produced is collected in the upper part of the boiler, ready for use in various applications such as power generation or heating.

- Exhaust: After transferring heat to the water, the cooled gases exit the boiler through the chimney or stack.

The steam rating in firetube boilers doesn’t exceed 2500 kg per hour and pressure is limited to 10 bars.

A firetube boiler is a type of boiler in which hot gases pass from a fire through one or (many) more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam

The firetube boiler developed as the third of the four major historical types of boilers: low-pressure tank or “haystack” boilers, flued boilers with one or two large flues, firetube boilers with many small tubes, and high-pressure watertube boilers. Their advantage over flued boilers with a single large flue is that the many small tubes offer a far greater heating surface area for the same overall boiler volume.

The general construction is as a tank of water penetrated by tubes that carry the hot flue gases from the fire. The tank is usually cylindrical for the most part—being the strongest practical shape for a pressurized containerand this cylindrical tank may be either horizontal or vertical.

This type of boiler was used on virtually all steam locomotives in the horizontal “locomotive” form. This has a cylindrical barrel containing the fire tubes, but also has an extension at one end to house the “firebox”.

This firebox has an open base to provide a large grate area and often extends beyond the cylindrical barrel to form a rectangular or tapered enclosure.

The horizontal fire-tube boiler is also typical of marine applications, using the Scotch boiler; thus, these boilers are commonly referred to as “scotch-marine” or “marine” type boilers.

Vertical boilers have also been built of the multiple fire-tube types, although these are comparatively rare; most vertical boilers were either flued or with cross water-tubes.

Operation

A locomotive boiler is a type of firetube boiler that uses the heat from burning fuel to create steam. The combustion process takes place in the firebox, which is located at the front of the boiler. The hot combustion gases then pass through a series of fire tubes that are surrounded by water. The water absorbs the heat from the gases and turns into steam. The steam rises to the top of the boiler, where it is collected in the steam dome. The steam dome also contains the regulator, which controls the flow of steam out of the boiler.

In some locomotive boilers, the steam is further heated by passing it through a superheater. The superheater is a series of tubes that are heated by the hot combustion gases. The superheated steam is then used to power the steam engine. The waste gases from the combustion process are expelled through the chimney.

The air circulation within a locomotive boiler is created by the tall smokestack. The smokestack creates a draft, which draws air into the firebox and helps to keep the fire burning. In some locomotives, the exhaust steam from the cylinders is also directed into the smokestack. This creates a stronger draft and helps to improve the efficiency of the boiler.

The Rocket locomotive was a major innovation in locomotive history. It was the first locomotive to use a multi-tubular boiler. This design had a much higher steam production rate than previous designs, which allowed steam locomotives to become more powerful.

Fire Tube Boiler Construction

- Fire tube boiler consists of a vertical, cylindrical shell, equipped with a firebox in the bottom, water space in the middle portion and steam space in the upper portion.

The fire grate is placed at the bottom of the firebox and coal is fired at the firebox. An ash pit is located at the bottom of the grate to collect the ash of burnt coal, which is periodically removed.

- One or more cross tubes are either flanged or riveted to the water space located in the firebox to increase the heating surface area to improve the water circulation.

A short chimney is connected at the top of the firebox to discharge the waste flue exhaust gases at some greater height. Manhole and hand holes are provided for cleaning the interior of the boiler shell and cross tubes.

- The boiler consists of a pressure gauge, water level indicator, safety valve, steam stop valve, and a manhole as mountings to provide safety and ease of working.

Fire Tube Boiler Working

Fuel burns on the grate in the firebox. The resulting hot flue gases are allowed to pass around the cross tubes.

The water surrounding the cylindrical firebox also receives heat by convection and radiation. Thus steam is produced. The water circulation in the boiler depends on the density difference in water, created by the temperature difference in water

Types of Fire Tube Boilers

- Cornish boiler

- Lancashire boiler

- Locomotive boiler

- Scotch marine boiler

- Admiralty-type direct tube boiler

- Horizontal return tubular boiler

- Immersion fired boiler

- Vertical fire-tube boiler

FAQ

A fire tube boiler is a type of boiler in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

There are three main types of fire tube boilers: scotch marine boilers,water tube boiler, and locomotive boilers. Scotch marine boilers are the most common type of fire tube boiler. They are used in a variety of applications, including ships, power plants, and industrial facilities. Water tube boilers are less common than scotch marine boilers, but they offer a number of advantages, including higher efficiency and lower maintenance costs. Locomotive boilers are a type of fire tube boiler that is specifically designed for use in locomotives. They are characterized by their small size and lightweight design.

Simple design

Low cost

Easy to operate and maintain

Flexible in terms of application

Wide range of sizes and capacities are available

Fire tube boilers work by burning fuel to heat water in a sealed container. The hot water turns into steam, which is then used to power machinery or heat buildings. The steam is generated in a series of tubes that run through the water. The heat from the fire is transferred to the water through the walls of the tubes.

The main parts of a fire tube boiler are:

Firebox: The firebox is where the fuel is burned.

Water tubes: The water tubes are the tubes that carry the water.

Steam drum: The steam drum is where the steam is collected.

Superheater: The superheater is where the steam is heated to a higher temperature.

Safety valve: The safety valve is a valve that opens to release steam if the pressure gets too high.

Fire tube boilers require regular maintenance to ensure that they operate safely and efficiently. Some of the key maintenance tasks include:

Cleaning the boiler: The boiler should be cleaned regularly to remove scale buildup and other debris.

Checking the water level: The water level should be checked regularly and topped up as needed.

Testing the safety valve: The safety valve should be tested regularly to ensure that it is working properly.

Replacing worn parts: Worn parts should be replaced as needed to prevent damage to the boiler.

Fire: The firebox can become hot enough to ignite combustible materials.

Explosion: The steam pressure in the boiler can build up to dangerous levels.

Burns: The hot water and steam can cause serious burns.

Corrosion: The hot water and steam can cause the boiler to corrode.

Here are a number of fire safety precautions that should be taken when operating a fire tube boiler, including:

Never leave a burning fire unattended.

Keep combustible materials away from the boiler.

Install a fire alarm and extinguisher in the boiler room.

Have the boiler inspected by a qualified professional on a regular basis.

Boiler manuals

Online resources

Technical training courses

Safety seminars