A deaerator tank is a device used to remove dissolved gases from water. It is typically used in steam boilers to remove dissolved oxygen and carbon dioxide from the feedwater. Dissolved oxygen and carbon dioxide can cause corrosion in steam boilers, so removing them helps to extend the life of the boiler.

Deaerator Tank in Boiler

What are Deaerator Tanks

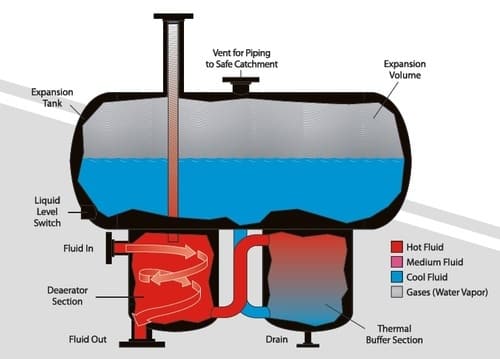

The Deaerator tank in the boiler acts as a Feed Water Tank to store cold and hot fluid in order to remove dissolved air or non-condensable gases from the fluid. Deaerating feed tank helps in removing non-condensable gases from a feed.

Thermodyne manufactures Deaerator tanks that suit the customer’s needs.

Deaerator Tanks Uses

Water or any fluid which is used as a medium for heat transfer generally contains Oxygen and other non-condensable gases in it. These gases dissolved in a fluid act as insulation to heat transfer. Due to the presence of these gases in a fluid, heat transfer rates from fuel to fluid are generally reduced which in turn will increase the fuel required for heating, thereby decreasing the efficiency.

In a deaerator tank ( aka Feed Water Tank), carbon dioxide (CO2), Non-dissolved Gas, and oxygen (O2) are released as gases and combined with water (H2O) to form carbonic acid, (H2CO3).

Deaerator Tank Working Principle

Deaerator working principle

The solubility of gases in a fluid decreases with an increase in the temperature of a fluid and the pressure of gas in a fluid is directly proportional to the partial pressure of gas above it, so removing the gas above the fluid decreases the pressure above the fluid and causes the gas dissolved in a fluid to escape the fluid in order to balance the pressure.

Condensate or process fluid returning from the process is generally at high temperature than the ambient temperature and the fluid which needs to be fed is at a lower temperature than the ambient. Both the feed and process fluid is kept together in a tank in order to increase the temperature of the feed by taking heat from the process fluid.

Also Read : Thermic Fluid Heater

Sometimes some part or partial steam is also injected into a tank through a perforated steam pipe to heat the feed water and maintain its operating temperature. The level of fluid in a tank is such that, some space above the fluid is kept free for the air to escape the fluid. An air vent is provided at the top of the tank so that all the air could escape the tank leaving behind any vapor formed.

Thermodyne Boilers manufactures deaerator tanks that come with adequate controllers for easy operation. Our deaerator tank is provided with the water level controller and the gauge glass to monitor and control the water level in the tank.

Safety Valve is provided on the top of the Deaerator tank to prevent the operating pressure of the tank to exceed the design pressure.

Deaerator tanks work by spraying the feedwater into a chamber where it is heated by steam. The heat causes the dissolved gases to come out of the solution and be vented from the tank. The treated water then falls into a storage tank below the deaerator.

Deaerator tanks come in a variety of sizes and configurations. The size of the tank is determined by the amount of feedwater that needs to be treated. The configuration of the tank is determined by the specific application.

Deaerator tanks are an essential part of steam boilers. They help to extend the life of the boiler and prevent corrosion.

Here are some of the benefits of using a deaerator tank:

- Reduces corrosion in steam boilers

- Improves the efficiency of steam boilers

- Increases the life of steam boilers

- Reduces the cost of operating steam boilers

- Improves the quality of steam

- Reduces the environmental impact of steam boilers

Deaerator tanks are a valuable investment for any steam boiler system. They can help to extend the life of the boiler, improve its efficiency, and reduce its operating costs

Deaerator tank FAQ

A deaerator tank is a device used to remove dissolved oxygen from water. This is done by exposing the water to a vacuum, which causes the oxygen to come out of solution. Deaerator tanks are used in a variety of applications, including boilers, power plants, and chemical processing plants.

The purpose of a deaerator tank is to remove dissolved oxygen from water. Dissolved oxygen can cause corrosion and scaling in boilers and other equipment. By removing the oxygen, deaerator tanks help to extend the life of equipment and improve efficiency.

A deaerator tank works by exposing the water to a vacuum. This causes the oxygen to come out of solution and be drawn away from the water. The water is then heated, which helps to further remove the oxygen.

There are several benefits to using a deaerator tank. These include:

Reduced corrosion and scaling

Increased equipment life

Improved efficiency

Reduced emissions

There are a few drawbacks to using a deaerator tank. These include:

The initial cost of the tank

The cost of operating the tank

The need for regular maintenance

Deaerator tanks are used in a variety of applications, including:

Boilers

Power plants

Chemical processing plants

Food processing plants

Pharmaceutical manufacturing

There are two main types of deaerator tanks:

Vacuum deaerators

Steam-heated deaerators

Vacuum deaerators use a vacuum to remove the oxygen from the water. Steam-heated deaerators use steam to heat the water, which helps to further remove the oxygen.

Deaerator tanks should be maintained on a regular basis. This includes checking the water level, cleaning the tank, and replacing the filters.

There are a few signs that a deaerator tank may be malfunctioning. These include:

Increased corrosion and scaling

Reduced equipment life

Decreased efficiency

Increased emissions

If you suspect that your deaerator tank is malfunctioning, you should contact a qualified service technician.