Corrugation

Corrugation

Corrugation

Corrugation

Heating for Corrugating Rolls

- Steam from boilers is used to heat the corrugating rolls, enabling them to create the distinctive fluted pattern in corrugated board. The steam’s consistent high temperature helps maintain uniform fluting quality and precision during the corrugation process.

Glue Drying and Bonding

- Boilers supply steam to facilitate the drying and curing of the glue applied between layers of paper. This helps in creating a strong bond that holds the flutes and liner sheets together, forming a rigid, durable structure. A steady steam supply speeds up production by ensuring quick drying times.

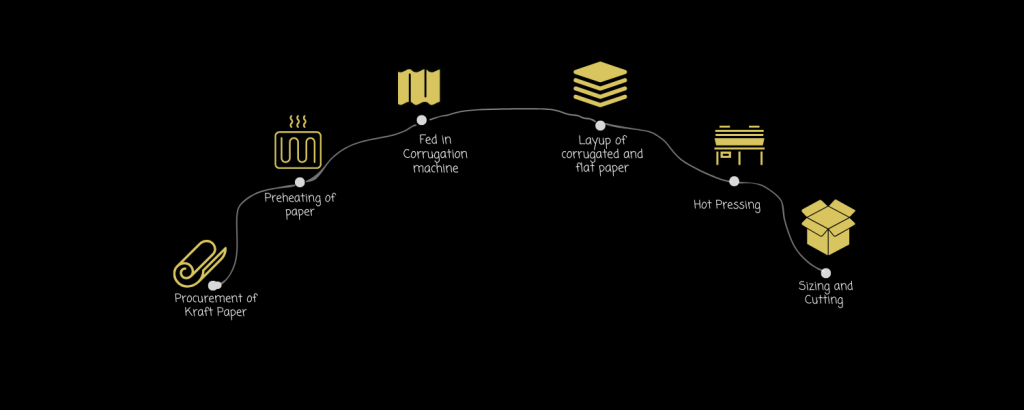

Paper Preheating

- In corrugation, the liner and medium papers are preheated to improve their flexibility and strength. Steam from boilers preheats these paper layers, making them more pliable and easier to mould without cracking, resulting in smoother corrugated board production.

Humidity Control

- Boilers assist in controlling the humidity levels in the production area. The steam generated can be used to maintain optimal moisture levels, preventing warping or brittleness in the corrugated sheets, thus improving the quality of the final product.

Energy for Production Line

- Corrugation plants typically run several machines simultaneously, all of which require energy. Boilers provide an efficient source of steam energy, which is essential for continuous, smooth production, reducing downtime, and enhancing productivity.

Thermal Treatment

- Some plywood products undergo thermal treatment to improve durability, moisture resistance, or fire resistance.

- Boilers generate the steam or heat required to perform these thermal treatments, ensuring uniform application.

Corrugation

Heating for Corrugating

Rolls

Rolls

- Steam from boilers is used to heat the corrugating rolls, enabling them to create the distinctive fluted pattern in corrugated board. The steam’s consistent high temperature helps maintain uniform fluting quality and precision during the corrugation process.

Glue Drying and Bonding

- Boilers supply steam to facilitate the drying and curing of the glue applied between layers of paper. This helps in creating a strong bond that holds the flutes and liner sheets together, forming a rigid, durable structure. A steady steam supply speeds up production by ensuring quick drying times.

Paper Preheating

- In corrugation, the liner and medium papers are preheated to improve their flexibility and strength. Steam from boilers preheats these paper layers, making them more pliable and easier to mould without cracking, resulting in smoother corrugated board production.

Humidity Control

- Boilers assist in controlling the humidity levels in the production area. The steam generated can be used to maintain optimal moisture levels, preventing warping or brittleness in the corrugated sheets, thus improving the quality of the final product.

Energy for Production Line

- Corrugation plants typically run several machines simultaneously, all of which require energy. Boilers provide an efficient source of steam energy, which is essential for continuous, smooth production, reducing downtime, and enhancing productivity.