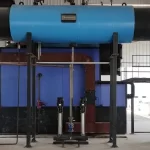

Combi Boiler Combitherm Ultra – Compact, Efficient, and Versatile Heating Solution

Combi Boiler - Combitherm Ultra

Combitherm Ultra Boiler, also known as a combi boiler or combination boiler, is a compact and factory-assembled boiler system designed for quick installation and minimal site work. The main advantage of this model over the standard Combitherm design is its space-saving layout, making it ideal for industries where installation space is limited.

Engineered with a hybrid construction, this advanced combi boiler combines the advantages of both water tube and smoke tube technologies. It is designed to optimize the heat transfer delivering high thermal efficiency and reliable performance.

One of the key highlights of this combi boiler model is its unique layout, where the shell is placed directly above the water tube membrane. This design allows faster water circulation, minimizes the risk of overheating, and enhances safety. Additionally, the smart placement of downcomers and riser tubes ensures smooth and efficient water flow within the system, ultimately extending the boiler’s operational life.

The combi boiler, Combitherm Ultra is highly versatile and can operate with a wide range of fuels. For rice husk applications, it features an automatic screw feeder and a fluidized bed combustion system to ensure efficient fuel handling.

With its compact footprint, multi-fuel compatibility, and robust performance, the Combitherm Ultra is an ideal combination boiler solution for various industries.

- Available in capacities from 1 TPH to 10 TPH for industrial steam needs

- All Biomass fuels, Rice husk, Briquettes, Coal, Agro-waste, Wood & wood chips

- Manual

- Fluidised Bed Combustion

- Automatic feeding

- Rice mills

- Distillery

- Paper

- Food processing

- Chemicals

- Rubber

- Dairy

- Textiles and others

- Compact Design – Requires very less floor space and minimal site work

- Multi-Fuel Flexibility – Supports wood, coal, briquettes, rice husk, and more

- Feeding Options – Available with both manual and automatic fuel feeding systems

- Factory-Assembled – Includes ducting, insulation, refractory, and structure work

- Low Maintenance – Easy access for cleaning and regular inspection

Suggested Products

Wastetherm- (Waste Heat Recovery Boiler)

Steam Accumulator

Book a free Consultation

Related Blogs

FAQs related to Combi Boiler Combitherm Ultra

A combi boiler (short for combination boiler) is a hybrid system that combines water tube and smoke tube designs to provide efficient heat transfer in a compact form.

The Combitherm Ultra features a more compact, space-saving design, requires less installation area, and offers faster water circulation due to its shell-above-membrane layout—making it more efficient and suitable for space-constrained industries.

The Combitherm Ultra is available in both manual and automatic fuel feeding options. For example, it uses an automatic screw feeder for rice husk applications to ensure consistent and efficient fuel handling.

Industries such as rice mills, food processing, textiles, paper, plywood, and chemicals benefit greatly due to the boiler’s flexibility, compactness, and multi-fuel capability.

This combi boiler is compatible with various solid fuels, including rice husk, wood, coal, briquettes, and petcoke, providing maximum operational flexibility.

Contact us for more details about our boilers, installations and services.