Boiler Valves are integral parts of any steam or heated water applications. Boiler valves are used as safety equipment in steam boilers to control pressure & control temperatures. Boiler valves are used to control the flow of steam or heated water in a boiler.

The main types of boiler valves are as follows:

What is the function of valve in boiler?

The valve in a boiler has several important functions. It regulates the flow of water or steam, ensuring proper pressure and temperature levels. It also acts as a safety measure, automatically closing to prevent overpressure situations and potential damage. Additionally, the valve allows for the isolation of specific sections of the boiler system for maintenance or troubleshooting purposes.

Ball Valve

Ball Valve is a quarter-turn operated valve. Ball Valves consist of a closure membrane which is a spherical plug with a through hole. A ball valve is a type of valve that uses a hollow, perforated ball to control the flow of fluid. The ball is rotated 90 degrees to open or close the valve. Ball valves are typically used in applications where a quick shutoff is required, such as in the water and gas industries. They are also used in applications where the flow of fluid needs to be controlled, such as in chemical processing plants.

When the valve is open the through hole is in line with the fluid flow and it allows the fluid to flow through it. The valve can be closed by rotating the globe by 90 degree. such that the hole now becomes perpendicular to the flow and thus stops the flow.

Its sheets are usually made up of soft materials to offer tight shutoff. Sometimes sheets can be made from plastic and metals. These valves are not recommended to be used in partial open conditions.

A large pressure drop occurs in open conditions of the valves due to misalignment between the direction of flow and the opening of the plug.

Gate valve

A gate valve is a sliding type of Boiler valve. In the gate valve, the closure membrane is a metal gate. A gate valve is a type of valve that uses a gate, or wedge, to control the flow of fluid. The gate is a flat plate that is attached to a stem. When the stem is turned, the gate moves up or down, blocking or allowing the flow of fluid.

These gates slide down to close the valve. The flow area is equal to the area of the pipe in fully open condition which results in negligible pressure drop across the valve.

These valves are usually used in on/off conditions. In partially open conditions due to vibrations, the valve is exposed to quick wear and tear. These valves find their use in the petrochemical industry due to the fact that they can work with metal-metal sealing.

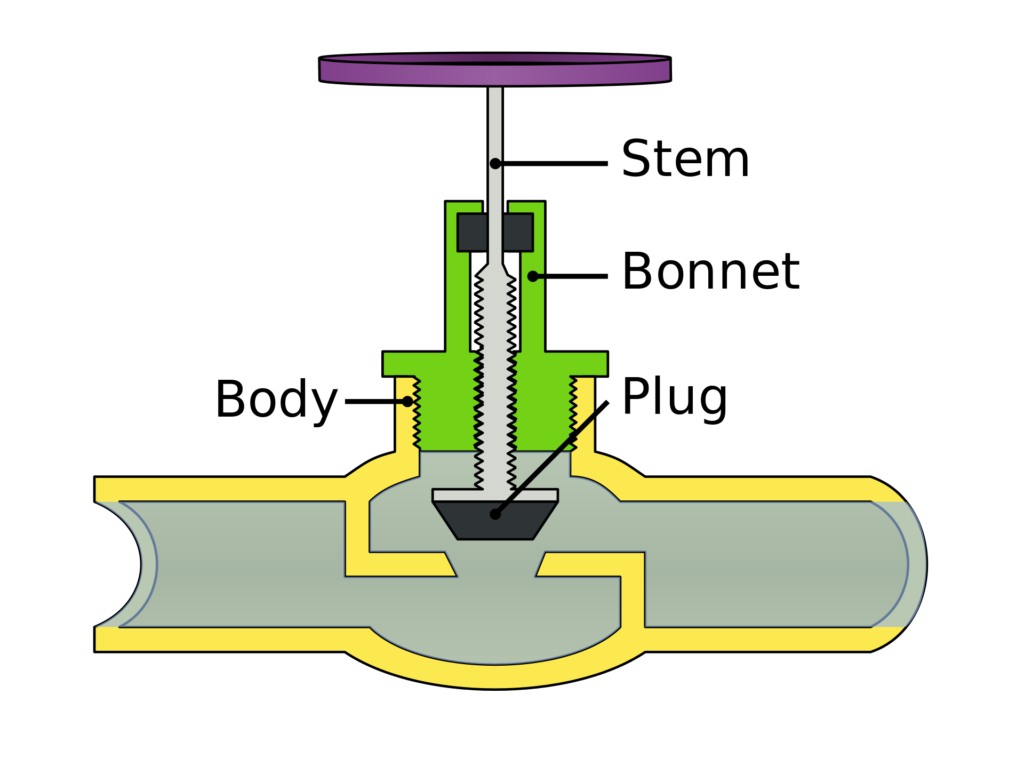

Plug valve

Like a ball valve, these valves are quarter-turn valves.

These boiler valves consist of a plug which can either be in the shape of a cylinder or conical.The plug also consists of a through slit which remains in line with the flow in the open condition.

When the plug is rotated by 90 Deg., this slit becomes perpendicular to flow and valves get closed.

Butterfly valve

A butterfly valve is a quarter-turn valve that uses a disc to control the flow of fluid. The disc is attached to a rod that is connected to an actuator. When the actuator is turned, the disc rotates 90 degrees. In the closed position, the disc blocks the flow of fluid. In the open position, the disc is perpendicular to the flow of fluid, allowing it to pass through the valve. These are the most simple and versatile steam boiler valves. These are also quarter-turn operated valves. quarter turn operation ensures quick operation of the valves.in opening condition, there is a minimum hindrance to the flowing fluid through the valves. This results in very less pressure drop across the valve.

Due to its unique mode of operation, the valve can be actuated easily without requiring wear and tear. its advantage is its compact size which makes its installation process easy.

Globe valve

A Globe valve is a linear motion type of valve and is typically used in both on/off conditions. globe valves, the flow of the fluid through the valve follows an S-path. A globe valve is a type of valve that is used to control the flow of fluids in a pipeline. It is a linear motion valve, which means that the closure member moves in a straight line. The closure member is a disc that is attached to a stem. When the stem is turned, the disc moves up or down, blocking or allowing the flow of fluid.

Due to this, the flow direction changes twice which results in higher pressure drops. Due to other advantages offered by them, they are widely used in applications where pressure drop through the valve is not a controlling factor.

These valves can be used in three configurations, depending on the applications-

- Tee pattern

- Angle Pattern

- Wye Pattern

Disc check valves

These are also called nonreturn valves as they allow the flow to pass through them only in one direction and stop the flow in another direction. Because of this unique property check valves are used in some critical applications in steam systems.

There are four major types of disc check valves as follows

Lift Check Valve

these work simply on the principle of gravity. When the fluid comes in the forward direction, the disc gets lifted from the seat against the gravitational force by the force of incoming fluid. The valve thus allows fluid to pass in this direction. When the fluid comes in the opposite direction, it supports the force of gravity and the disc remains on the seat, keeping the valve closed.

Swing Check Valve

In this kind of check valve, the disc or the closing element swings around a point to which it is hinged. When the fluid comes in the forward direction, the disc swings in an open position allowing the fluid to pass. When the fluid flow comes in the opposite direction, the disc swings and rests on the seat to lose it.

Spring-loaded Check Valves

In this kind of check valve, a tight shut-off is provided using a spring. the disc on the seat is held back by the spring. Even in the forward flow condition, the fluid should exert some pressure, called cracking pressure in order to open the disc against the spring pressure.

Diaphragm Type Check Valve

This kind of check valve uses diaphragms arranged in such a way that open to allow the flow only in the forward direction. When flow comes from the reverse direction, the diaphragms remain closed.

Steam Boiler Valves FAQ

- What are the different types of steam valves?

The most common types of steam valves are ball valves, gate valves, plug valves, butterfly valves, and globe valves. Each type of valve has its own advantages and disadvantages, so it is important to choose the right type for the application.

The factors to consider when choosing a steam valve include the pressure and temperature of the steam, the flow rate, the type of fluid, and the application. It is also important to consider the cost, the ease of maintenance, and the safety features of the valve.

Steam valves work by controlling the flow of steam. The valve opens to allow steam to flow, and closes to stop the flow of steam. The valve can be operated manually or automatically.

Steam valves offer a number of benefits, including:

They can control the flow of steam, which can help to improve efficiency and safety.

They can be used in a variety of applications, including heating, cooling, and power generation.

They are relatively easy to maintain and repair.

They are available in a variety of sizes and types, so they can be tailored to the specific application.

What are the drawbacks of using steam valves?

The main drawback of using steam valves is that they can be expensive. However, the benefits of using steam valves often outweigh the cost

Steam valves should be inspected and maintained on a regular basis to ensure that they are functioning properly. The frequency of inspection and maintenance will vary depending on the application.

There are a number of safety precautions that should be taken when working with steam valves, including:

Always wear safety glasses and gloves when working with steam valves.

Never operate a steam valve that is leaking or damaged.

Always open and close steam valves slowly and carefully.

Never put your hands or any other part of your body in the path of steam.

Steam valves can have a number of environmental impacts, including:

The use of steam can contribute to air pollution.

The Steam valves can have a number of environmental impacts, including:

The use of steam can contribute to air pollution.

The production of steam can use a significant amount of energy.

The disposal of steam condensate can be a problem. The production of steam can use a significant amount of energy.

The disposal of steam condensate can be a problem.

The future trends in steam valve technology include:

The development of more efficient and environmentally friendly steam valves.

The development of steam valves that are easier to maintain and repair.

The development of steam valves that are more resistant to corrosion and damage.

Steam valves can have a number of environmental impacts, including:

The use of steam can contribute to air pollution.

The production of steam can use a significant amount of energy.

The disposal of steam condensate can be a problem.