Rice Mill Boiler: How to Choose the Right Rice Mill Steam Boiler Before Buying

Selecting the Right Steam Boiler for Your Rice Mill Use Rice mill Boiler Claculator

Choosing the perfect steam boiler for your rice mill is a crucial decision that can significantly impact your production efficiency and overall success. To embark on this journey, follow these essential steps to make an informed choice:

Assess Your Rice Mill’s Requirements:

Before choosing a steam boiler, thoroughly evaluate your rice mill’s needs. This includes understanding the amount of rice paddy you process daily, your production goals, and any specific requirements your mill may have, such as variations in paddy rice types or parboiling milling processes. This assessment will help you select a boiler that can handle your mill’s workload effectively.

Efficiency and Energy Consumption:

Efficiency refers to how effectively a steam boiler converts the heat produced from fuel combustion into steam. It’s important to choose a boiler that can produce the required amount of steam while using the least amount of fuel. This not only saves money on fuel costs but also reduces environmental impact by conserving resources.

Application of Steam:

In a rice mill, steam is primarily used in the Parboiling process. The paddy is soaked in the water, steam is used to raise the temperature of paddy. After soaking, the paddy is taken to the dryer where the moist paddy is loaded for drying. The steam is connected to the heat exchanger whcih produces hot air through steam and this air is used to dry the paddy.

Boiler Safety Features:

Safety is paramount when operating steam boilers. Look for boilers equipped with advanced safety features such as pressure and temperature monitoring, automatic shutdown systems in case of anomalies, and reliable safety valves. These features ensure the protection of your mill and its workers from potential accidents.

Maintenance and After-Sales Support:

- A steam boiler requires regular maintenance to function optimally. When choosing a supplier or manufacturer, consider whether they offer maintenance plans and reliable after-sales support. This ensures that your boiler remains in good working condition, minimising downtime and unexpected repair costs.

Cost Considerations:

While it’s essential to manage costs, don’t focus solely on the initial purchase price of the boiler. Consider the long-term advantages, including energy savings and reduced maintenance costs. This broader perspective helps you make a decision that provides the best overall value for your investment.

Reputation and Customer Reviews:

Research the reputation of boiler manufacturers by reading customer reviews and seeking recommendations. A manufacturer with a positive track record and satisfied customers is more likely to provide a high-quality product and reliable support. Customer feedback offers valuable insights into the company’s philosophy & performance.

Seek Expert Advice:

Industry experts and experienced professionals can provide valuable insights into choosing the right steam boiler. They can help you navigate technical specifications, understand industry trends, and avoid common pitfalls. Seeking expert advice ensures that you make an informed decision tailored to your mill’s unique requirements.

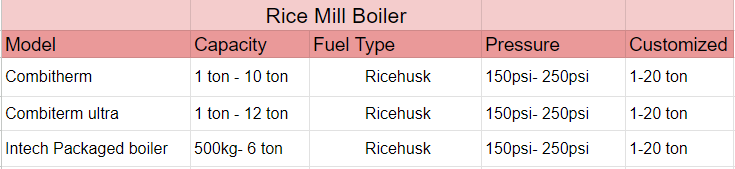

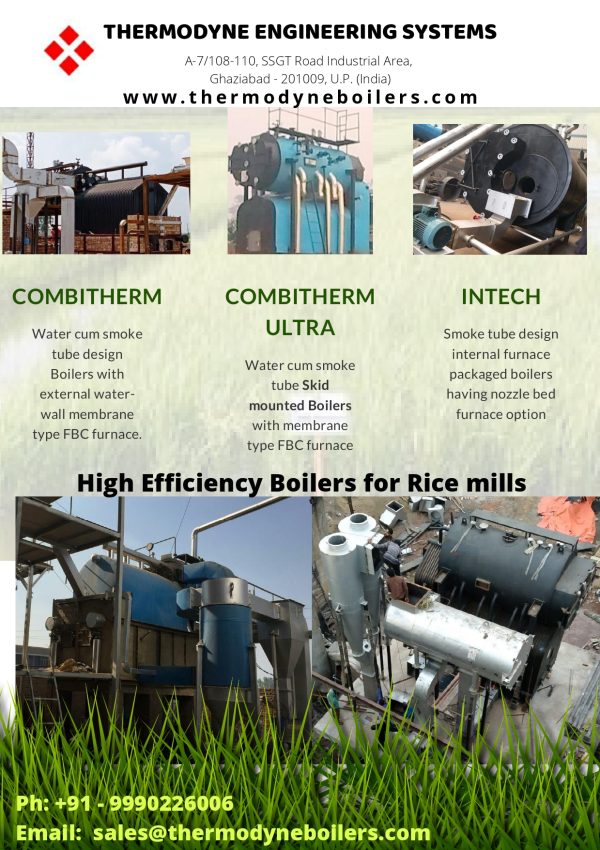

Thermodyne Boiler Models for Rice mills

Combitherm Boiler

A combitherm boiler is a type of hybrid boiler that combines both water tube and fire tube boiler technologies to efficiently generate steam for various capacities of rice mills. It offers versatility and energy efficiency in a single unit.

Combitherm Ultra Boilers

Combitherm Ultra Boilers (Combi Ultra Boiler) require minimum site work as they are factory assembled units and are mounted on a skid base frame. Their working is the same as our Combitherm model in a way that they too are the combination of water tube design and smoke tube design.

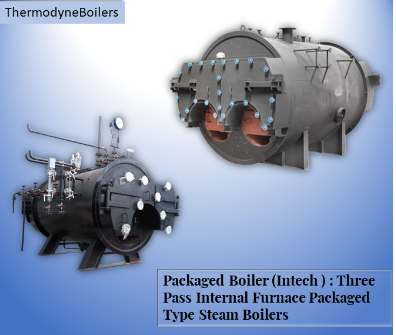

Packaged Boiler( intech boiler )

The Intec boiler, as its name suggests, is a packaged boiler with a 3-pass internal furnace Packaged boiler. It is a conventional 3 smoke-tube design approach and is intended for burning rice husk within an internal furnace.

These are the Model used in Rice mill industry all the necessary details below in table.

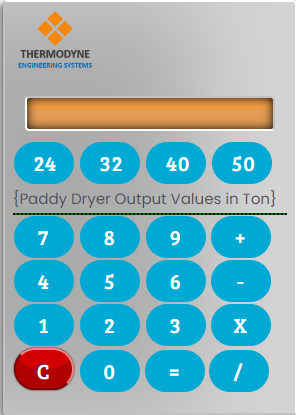

Ricemill Boiler Calculator Manual

To determine the boiler requirements for your paddy dryer, follow these steps:

Input the capacity of your paddy dryer in tons. For example, if you a 24-ton paddy dryer, enter 24.

The calculator will provide you with the recommended boiler capacity in tons. For a 24-ton paddy dryer, the recommended boiler capacity is 2 tons.

Using the Calculator:

Our Rice Mill Boiler Calculator is a user-friendly tool designed to simplify the process of determining your boiler needs. Simply input your paddy dryer capacity, and it will provide you with the required boiler capacity.

Paddy Dryer Capacity Reference:

24 Ton

32 Ton

40 Ton

50 Ton

For free Consultation

please call us at: +91 9990226006

The flyer of Rice mill boilers The video for rice mill industry

Unit 1: THERMODYNE ENGINEERING SYSTEMS,

A-7/110 SSGT Road Industrial Area,

Ghaziabad, UP, INDIA.

Unit 2: E-11 South East Zone MIA, Alwar – 301030, Rajasthan (India).

Phone : +91–120–4562332,

+91-1204110482

+91 9990226006

info@thermodyneboilers.com

sales@thermodyneboilers.com

sales1@thermodyneboilers.com