Food Processing

Application of steam boiler for food processing industry

Cooking and Heating

- Boilers supply steam to heat food products, ensuring consistent cooking temperatures. They are used in processes like boiling, steaming, and baking.

- Common applications include the preparation of canned food, dairy products, confectionery, and beverages.

Sterilization and Pasteurization

- Steam from boilers is used for sterilization of food products, equipment, and containers. This process is crucial in maintaining hygiene and extending the shelf life of products.

- Pasteurization involves heating milk, juices, and other beverages to destroy harmful microorganisms without affecting their flavor and quality.

Cleaning and Sanitation

- In food processing plants, boilers provide hot water and steam for cleaning and disinfecting equipment, facilities, and packaging materials. This ensures compliance with health standards.

Packaging

- Steam helps in sealing containers and bottles through steam tunnels and shrink-wrap applications. It ensures product integrity and prevents contamination.

Drying

- Boilers are used to generate hot air or steam for drying food products like fruits, grains, and spices. This reduces moisture content, preventing spoilage and enhancing product shelf life.

Concentration and Evaporation

- Boilers provide heat in processes like evaporation, where water is removed from liquids such as sauces, syrups, or dairy products to concentrate the product.

Blanching

- Steam from boilers is used in blanching, a process that involves briefly heating food products (e.g., vegetables) to preserve their color, flavor, and nutritional value before freezing or further processing.

Energy Source

- Boilers also serve as a primary energy source for cogeneration systems in food processing plants, generating both electricity and heat for various operations.

Application of steam boiler for food processing industry

Cooking and Heating

- Boilers supply steam to heat food products, ensuring consistent cooking temperatures. They are used in processes like boiling, steaming, and baking.

- Common applications include the preparation of canned food, dairy products, confectionery, and beverages.

Sterilization and

Pasteurization

Pasteurization

- Steam from boilers is used for sterilization of food products, equipment, and containers. This process is crucial in maintaining hygiene and extending the shelf life of products.

- Pasteurization involves heating milk, juices, and other beverages to destroy harmful microorganisms without affecting their flavor and quality.

Cleaning and Sanitation

- In food processing plants, boilers provide hot water and steam for cleaning and disinfecting equipment, facilities, and packaging materials. This ensures compliance with health standards.

Packaging

- Steam helps in sealing containers and bottles through steam tunnels and shrink-wrap applications. It ensures product integrity and prevents contamination.

Drying

- Boilers are used to generate hot air or steam for drying food products like fruits, grains, and spices. This reduces moisture content, preventing spoilage and enhancing product shelf life.

Concentration and

Evaporation

Evaporation

- Boilers provide heat in processes like evaporation, where water is removed from liquids such as sauces, syrups, or dairy products to concentrate the product.

Blanching

- Steam from boilers is used in blanching, a process that involves briefly heating food products (e.g., vegetables) to preserve their color, flavor, and nutritional value before freezing or further processing.

Energy Source

- Boilers also serve as a primary energy source for cogeneration systems in food processing plants, generating both electricity and heat for various operations.

Our Customers From food processing industry

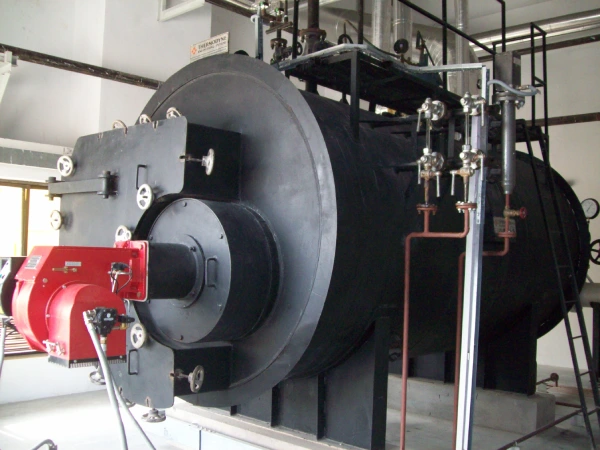

Boiler Options for food processing industry

Savemax

1 TPH to 20 TPH

Intech

500 kg/hr – 6000 kg/hr

Revosteam

100 kg/hr – 900 kg/hr

Combitherm Ultra

1 TPH to 10 TPH