Thermodyne Engineering Systems

What is Biomass Boiler

Biomass boilers are a sustainable alternative to traditional gas boilers. They use wood pellets to produce heat, which is essentially carbon neutral because the carbon dioxide released during combustion was absorbed by the tree while it was growing. This makes biomass boilers a great way to reduce your carbon footprint and help fight climate change.

In addition to being carbon neutral, biomass boilers are also a good way to use waste wood. Each year, approximately 8.5 million tonnes of wood goes into landfill in the UK. This wood could be used to fuel biomass boilers, which would not only provide heat and hot water, but would also help to reduce the amount of waste going to landfill.

If you are looking for a sustainable and environmentally friendly way to heat your home, then a biomass boiler is a great option. They are efficient, reliable, and cost-effective. Plus, they help to reduce your carbon footprint and fight climate change.

some additional benefits of using biomass boilers:

- They can provide heat for both space heating and hot water.

- They are relatively easy to install and maintain.

- They can last for many years with proper care.

- They can be a good investment for homeowners who want to save money on their energy bills.

Industrial Biomass Boiler : Energy solutions based on biomass and bio-fuels provide clean and renewable energy for large national and international companies. Green-thinking companies are now using biofuels to mitigate the impact their activities have on the environment by reducing emissions of greenhouse gases.

Biomass Boiler – Industrial Applications

Biomass Steam Boilers Importance in Industrial Applications

- Bio-fuel fired boiler systems can also generate earnings for your company by saving money on energy costs, and by the sale of carbon credits. Achieve energy independence, get off the Gas Grid, and no longer be at the mercy of the oil markets.

- Our Boiler’s Gasification and Gasifier Boiler Systems will strengthen your bottom line by reducing, or even eliminating your energy and disposal costs altogether, through the combustion of renewable fuel sources, also known as Biomass.

Our Biomass Boiler & Your Business’s Improved ROI

Thermodyne Biomass Boiler Systems provide successful strategies and techniques which can reduce the operational costs of current facilities and provide an ROI from installation in new construction.

As the overall market sets on the path of environmental sustainability and energy costs continue to increase, industry leaders will be hard pressed to find economically viable solutions to stay ahead of the curve.

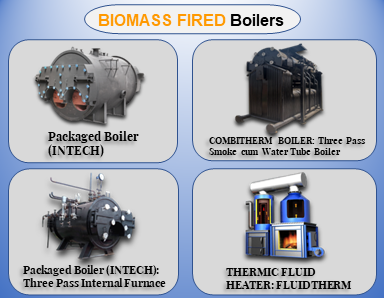

Thermodyne : Biomass Steam Boiler Model

Thermodyne Boiler is a leader in the development of boiler technology and energy management projects through sustainable solutions for renewable energy and energy efficiency by biomass fuel.

Why Biomass Boiler for Your Plant ?

Biomass Boiler Manufacture : We are one of the best biomass boiler manufacturer in India, we have other types of boilers that are used in industries.

Biomass Boiler Specs : Various Boiler designs are suitable for applications to produce high pressure steam or hot water in ranges from 3,450 – 60,000 lbs/hr (3.4 mmBTU – 60 mmBTU) output from 100 up to 900 PSI.

After Sale Support : Thermodyne Boiler provides its clients with the support and expertise necessary to design, fabricate and install complete solid fuel boiler systems, from the fuel storage system thru exhaust gas emission mitigation.

Boiler Fuels: Consider trading fossil fuels for agricultural biomass, wood, bark, agave fibre, rice husk, chicken manure, sugar cane bagasse, king grass, MSW, construction debris, nuts, shells, husks, paper, card/board products, hog fuel, sawdust, shavings, and/or sludge.

Better Business ROI : Profiting from the implementation of energy efficient and sustainable technology will be necessary to maintain a competitive advantage.

Environment-Friendly Solution: Alternative Fuel Solutions and Thermodyne packaged projects can help you reduce carbon, reduce emissions, and reduce both operating and fuel costs, as well as being eligible to sell your carbon credits.

Biomass Steam Boilers – Energy Efficiency & Environmentally Sustainability

Let Thermodyne Boiler help you implement the next generation of technologies in today’s facilities. Discover how to obtain immediate benefits from current environmental initiatives.

Take advantage of environmental and energy reducing strategies in new construction and retrofit projects. These are just some of the latest

- Take advantage of environmental and energy reducing strategies in new construction and retrofit projects. These are just some of the latest

developments in Biomass Boiler Technology that Thermodyne can provide to benefit your business and your bottom line!

Industrial Biomass Steam Boiler FAQ

A biomass boiler is a type of heating system that burns biomass fuel, such as wood pellets, wood chips, or agricultural waste, to generate heat.

Biomass boilers offer a number of benefits, including:

They are a renewable energy source, which means they do not produce greenhouse gases.

They are more efficient than traditional heating systems, such as gas boilers, which can save you money on your energy bills.

They can be used to heat your home, hot water, or even generate electricity.

There are three main types of biomass boilers:

Wood pellet boilers: These boilers are designed to burn wood pellets, which are small, compressed pieces of wood.

Wood chip boilers: These boilers are designed to burn wood chips, which are larger pieces of wood that have been chopped into small pieces.

Agricultural waste boilers: These boilers are designed to burn agricultural waste, such as corn stover, wheat straw, or rice hulls.

When choosing a biomass boiler, you should consider the following factors:

The size of your home or business

The amount of heat you need

The type of fuel you want to use

The efficiency of the boiler

The cost of the boiler

The cost of installation

The cost of a biomass boiler varies depending on the size, type, and efficiency of the boiler. In general, biomass boilers cost more than traditional heating systems, such as gas boilers. However, the cost of biomass boilers can be offset by the savings you can achieve on your energy bills.

Biomass boilers can be installed by a qualified installer. The installation process will vary depending on the type of boiler you choose.

Biomass boilers require regular maintenance to ensure they operate efficiently and safely. The frequency of maintenance will vary depending on the type of boiler you choose.

The most common problems with biomass boilers include:

Combustion problems

Ash buildup

Boiler leaks

Boiler fires

If you experience problems with your biomass boiler, you should contact the manufacturer or a qualified installer.

Biomass boilers can be purchased from a variety of retailers, including online retailers, home improvement stores, and heating and cooling contractors.

Send Enquiry for Industrial Biomass Boiler

Talk to our engineers & sustainable energy experts regarding your steam generation requirement, biomass fuel fired steam boiler systems cost, & profitability factors related to our biomass boiler model

Thermodyne Industrial Boiler Manufacturer In India

- Boiler Losses That Eat Away Your Profits

- Dissolved Gases in Feed Water and Its Effect

- Pressure Reduction System

- How to minimize the Blowdown Losses