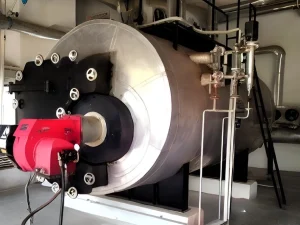

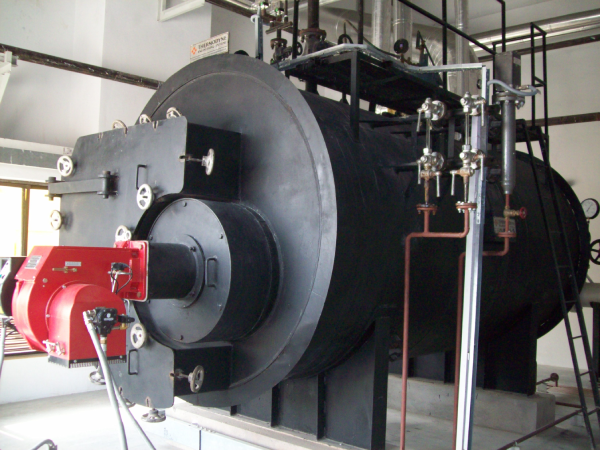

Oil Fired Boiler (Savemax) – Engineered for Superior Efficiency, Reliability & Industrial Performance

Oil Fired Boiler -Savemax

The Savemax is a three-pass, smoke-tube design, gas or oil fired boiler with an internal water-cooled furnace. This design ensures high efficiency and optimal performance, making it the ideal choice for various industrial applications.

Featuring a standard three-pass internal furnace smoke tube configuration with water enclosed reversal chamber. This design ensures enhanced heat transfer as the reversal chamber and the furnace are surrounded by water on all sides, making effective heat transfer of the flue gases to the water. The flue gases travel through the tubes in the 2nd and 3rd passes, delivering maximum heat to the water thereby producing steam efficiently.

1 TPH- 20 TPH

- Light oil

- Heavy oil

- PNG

- LPG

- Biogas

- Oil fired

- Gas fired

- Dual fuel fired (Oil cum gas)

- Pharmaceuticals

- Textiles

- Food processing

- Chemicals

- Rubber

- Dairy

- Beverages and others

Oil fired boiler related FAQ's -

An oil fired boiler is a type of industrial boiler that uses oil—such as light diesel oil, furnace oil, or heavy oil—as its primary fuel source to generate steam or hot water for various industrial processes

Oil fired boilers can use the following types of oil:

Light Diesel Oil (LDO)

Furnace Oil (FO)

Heavy Oil

These are the most common fuel oils used for industrial oil fired boilers

The oil fired boiler working process involves burning fuel oil in a combustion chamber. The heat produced transfers to water through a heat exchanger, generating steam or hot water for industrial use. Exhaust gases are safely expelled through the flue system.

Yes, oil fired steam boilers are available in both low and high-pressure configurations to meet industrial demands.

Key components include:

Burner (for oil combustion)

Combustion chamber

Heat exchanger

Water tubes or shell

Steam drum (for steam boilers)

Flue gas ducting and chimney

Control systems and safety devices

Oil fired boilers are widely used in industries such as food processing, chemical manufacturing, textile, pharmaceuticals, paper, and small-scale manufacturing where reliable steam or hot water is required.

High efficiency and rapid steam generation

Consistent and controllable heat output

Suitable for locations without access to natural gas

Compact design options for limited space industries

Lower emissions with modern burners and controls

Consider the following factors:

Required steam or hot water output (capacity)

Operating pressure

Fuel type and availability

Space constraints

Efficiency ratings

Budget and operational costs

Maintenance requirements

Common types include:

Scotch marine boiler

Locomotive boiler

Cornish boiler

Lancashire boiler

Vertical fire-tube boiler