Thermodyne Engineering Systems

Optimizing Industrial Output through Cutting-edge Oil Fired Boilers: Exploring Innovative Solutions

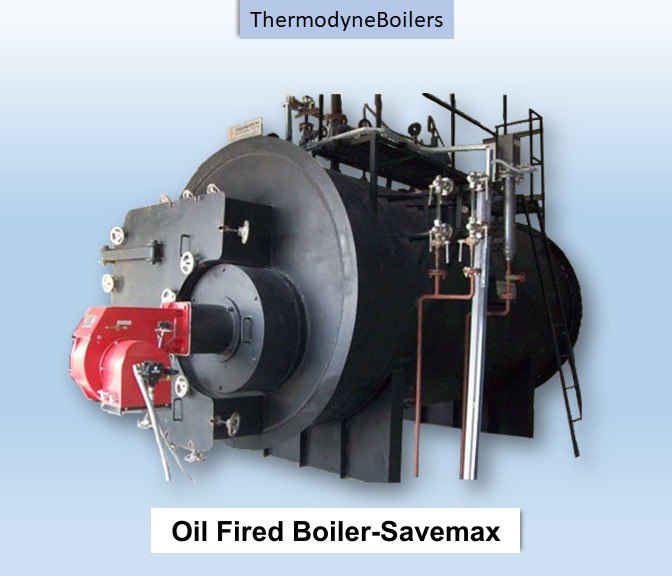

Savemax – Oil Fired Boilers are a basic three-pass smoke tube boiler inside the furnace style in which flue gasses are in the tubes and water is located outside the tubes within the shell. The combustion of oil in a furnace demands the atomization of fuel. The fuel that is introduced to the furnace in large quantities is liquid form, it is required to be separated into fine droplets, so that each part of the fuel can be ignited without leaving trace.

The process of separating fluid particles is referred to as Atomization. In general, atomization occurs with the aid of an air-driven fan which provides air to aid in combustion. burning of the gasoline. Most burners have an attached fan, and the assembly is referred to as an Monobloc Burner which means fan attached to a burner.

The outstanding features make the boiler an ideal choice for the sector of Thermodyne.

The 3-pass oil-heated boilers are ideal for burning fuels such as light and heavy oils.

Each Oil boiler is very efficient, as the temperature of the furnace in the case of both is approximately 1200-1300oC. The higher the temperature in the furnace greater will be the rate of radiation heat transfer to the water surrounding. The huge combustion volume, huge water and Steam storage capacity, as well as superior design, make it efficient to operate.

Types of oil-fired steam boilers:

There are several types of oil-fired steam boilers available in the market. Some of the common types include:

Fire-tube boilers: In these boilers, the hot gases produced by the burning oil pass through the tubes, heating the water in the tube.

Water-tube boilers: In these boilers, the water is circulated through the tubes, and the hot gases produced by the burning oil pass around the tubes.

Coil-type boilers: In these boilers, the heat exchanger is made up of coiled tubes, and the water is heated by the hot gases produced by the burning oil.

Advantages of oil-fired steam boilers:

- Oil-fired steam boilers have several advantages over other types of boilers. Some of the advantages include:

- Efficiency: Oil-fired steam boilers are highly efficient and can produce steam quickly.

- Reliability: Oil-fired steam boilers are highly reliable and can operate continuously for extended periods.

- Low maintenance: Oil-fired steam boilers require less maintenance compared to other types of boilers.

- Fuel availability: Oil is readily available in many parts of the world, making it an easily accessible fuel source.

- Cost-effective: Oil-fired steam boilers are cost-effective compared to other types of boilers.

Oil fired steam boilers are a crucial component in many industries, including power generation, chemical processing, and petroleum refining. These boilers are used to generate steam by heating water using oil as the fuel. The steam produced is used for various purposes, such as power generation, process heating, and space heating. In this article, we will provide comprehensive information about oil-fired steam boilers and how they work.

“Our Savemax Boilers are oil-fired fire tube boilers, which means they are operated using oil as a fuel source”

Capacity:-

The oil-fired Savemax Boiler is offered in sizes ranging from 1 TPH to 10 TPH.

Fuel:

The oil-fired boiler can operate using liquid fuels such as heavy or light oil, as well as gaseous fuels like natural gas.

Other Steam Product manufacture by Thermodyne