Boilers Losses That Eat Away Your Profits

Every user of a boiler should be aware of some of the significant losses linked to boiler operation, which include the following:

Loss due to dry flue gas

Loss due to dry flue gas

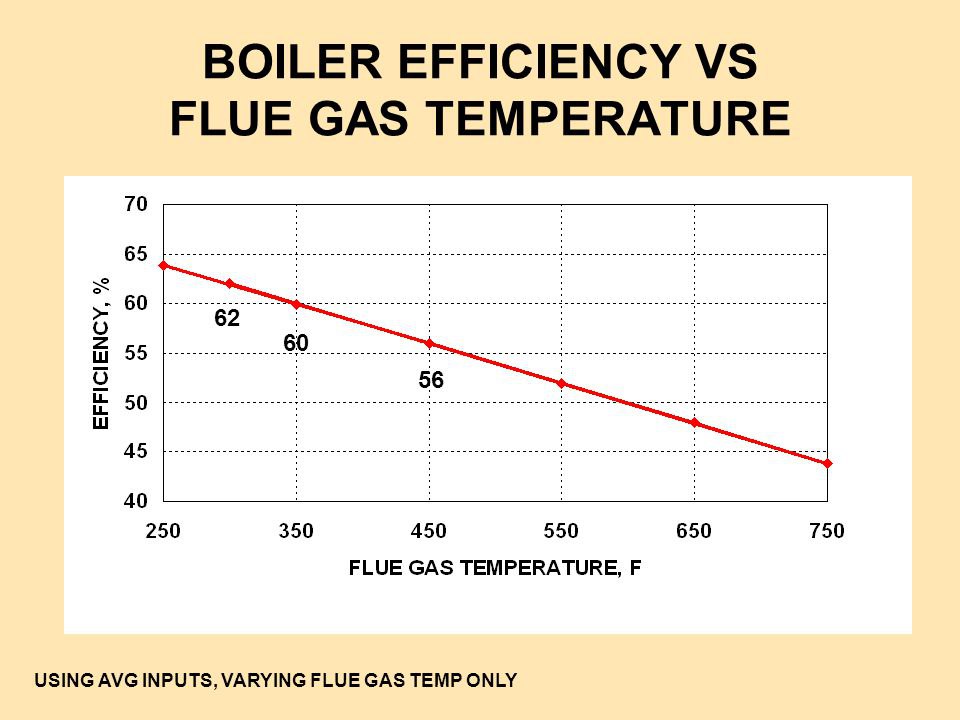

The temperature of the flue gas is one of the main sources of energy losses during boiler operation. Flue gases carry heat with them and release it into the environment because their temperature is higher than the ambient temperature. The loss will be greater the higher the flue gas temperature.

Although it is not practical to have flue gas temperatures that are identical to their surroundings, they should nonetheless be kept as low as feasible. It is defined as the difference between the enthalpy

of flue gases emitted out of the boiler and the enthalpy of flue gases cooled down to the ambient temperature per amount of heat produced by 1 kg of fuel.

Loss due to moisture in fuel

Loss due to moisture in fuel

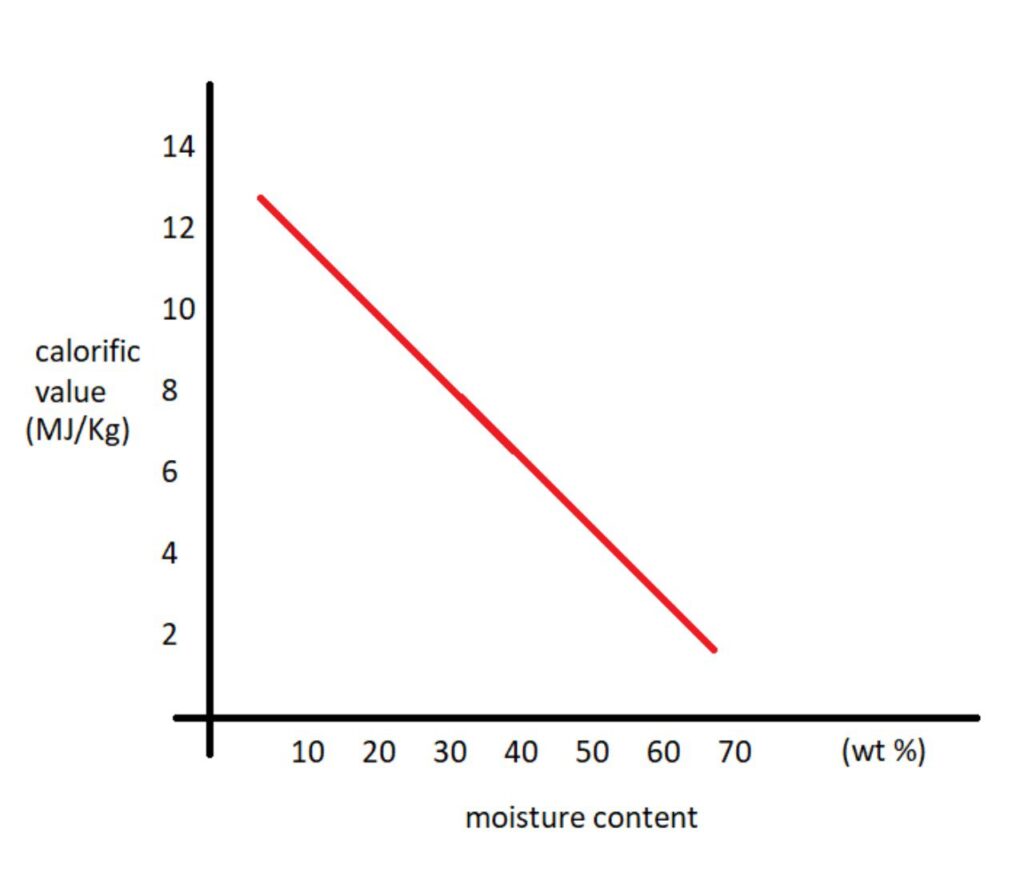

Coal, briquettes, and husk are examples of solid fuel that are particularly effective at absorbing moisture from the air. The fuel’s calorific value and combustion efficiency are both decreased by this moisture. When this moist fuel is burned in the furnace, water vapor is produced in the flue gases, which lowers the stack temperature.

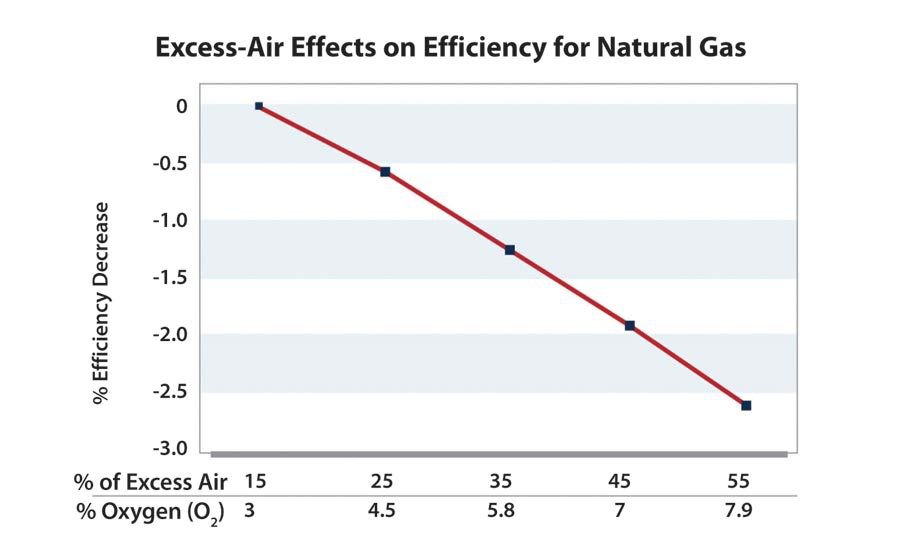

Loss due to excess air

Despite the fact that air is necessary for complete fuel combustion, utilizing more air than is required could be costly since excess air is cooler than required and absorbs heat from the fuel flame. It further causes the heat transfer to the boiler to be reduced. This air, along with waste flue gases, carries this heat away. As a result, boiler systems waste energy when there is too much air. For every 10% reduction in excess air, boiler efficiency increases by 0.5%.

Loss due to excess air

Heat loss due to incomplete combustion

The supply of air provides the oxygen needed for continuous and complete fuel burning. In total combustion, carbon and oxygen react to form carbon dioxide, while hydrogen and carbon dioxide react to form water. When there is insufficient air, carbon is oxidized, producing CO instead, which produces less heat and results in incomplete combustion.

Bottom ash loss

Bottom Ash Loss can be determined using the temperature and carbon content of the ash and is dependent on the properties of the coal. The carbon in the ash is what truly matters, not its temperature, which only has a modest impact on ash loss. The related bottom ash energy loss at 350 oC, assuming a 22 percent carbon content in the ash, will typically be as follows:

Carbon energy loss equals 3,6%

Ash temperature loss is equal to 0.18%.

4,78% of the bottom was lost to ash

Conclusion

From the aforementioned reasons, it is obvious that these losses might have a negative impact on the operation of the boiler and the organization’s earnings. The reduction of these losses is crucial.

Therefore, whether you are a boiler operator, user, or planning to purchase a new boiler but are unsure on how to choose the boiler, feel free to contact us. A variety of energy-efficient boilers are offered by THERMODYNE ENGINEERING SYSTEMS.

Boiler losses are the heat that is lost from a boiler during the combustion process. This can be due to a number of factors, including the moisture content of the fuel, the high temperature of the stack gases, the material’s low conductivity, or impurities in the feed water.

Stack losses: These are the heat losses that occur when the flue gases leave the boiler.

Radiation losses: These are the heat losses that occur when heat is radiated from the boiler’s surface to the surrounding environment.

Convection losses: These are the heat losses that occur when heat is convected from the boiler’s surface to the surrounding environment

The causes of boiler losses can vary depending on the type of boiler and the operating conditions. However, some of the most common causes include:

Moisture content of the fuel: The moisture content of the fuel can reduce the efficiency of the boiler by absorbing heat.

High temperature of the stack gases: The high temperature of the stack gases can also reduce the efficiency of the boiler by carrying away heat.

Material’s low conductivity: The material’s low conductivity can reduce the efficiency of the boiler by making it difficult for heat to transfer from the combustion chamber to the water.

Impurities in the feed water: Impurities in the feed water can reduce the efficiency of the boiler by forming scale on the boiler’s surface, which can reduce heat transfer.

There are a number of ways to minimize boiler losses, including:

Using a fuel with a low moisture content.

Reducing the temperature of the stack gases.

Using a material with a high conductivity.

Removing impurities from the feed water.

Maintaining the boiler properly.

Minimizing boiler losses can lead to a number of benefits, including:

Increased efficiency: By minimizing boiler losses, you can increase the efficiency of your boiler, which can save you money on fuel costs.

Reduced emissions: By minimizing boiler losses, you can reduce the amount of pollutants emitted from your boiler, which can help to improve air quality.

Increased safety: By minimizing boiler losses, you can reduce the risk of fires and explosions, which can help to improve safety.

The costs of minimizing boiler losses can vary depending on the type of boiler and the operating conditions. However, in general, the costs of minimizing boiler losses are relatively low compared to the benefits.

The best practices for minimizing boiler losses include:

Using a fuel with a low moisture content.

Reducing the temperature of the stack gases.

Using a material with a high conductivity.

Removing impurities from the feed water.

Maintaining the boiler properly.

The signs of boiler losses can include:

Increased fuel consumption.

Reduced boiler efficiency.

Increased emissions.

Boiler fires or explosions.

The consequences of boiler losses can include:

Increased fuel costs.

Reduced air quality.

Increased safety risks.

Boiler fires or explosions.

If you are concerned about boiler losses, you can get help from a number of sources, including:

Your boiler manufacturer.

A qualified boiler technician.

A government agency that regulates boilers.