How to Prevent Boiler Corrosion

Even the most aggressive forms of prevention can’t stop minor corrosion from eventually happening. But, with the right approach, the symptoms of corrosion can be reduced and the life of your boiler extended.

Here are some methods which anyone can follow to reduce the corrosion inside the boiler-

- Treat Water- Additives ensure that all oxygen in the feedwater that reaches the boiler is quickly consumed. These additives prevent oxygen from forming corrosive cells and blisters. Keep on top of the boiler water by working with a reputable water chemistry firm.

- Use of Barrier Coatings: Barrier coatings such as paint, fiber, or powder are one of the simplest and inexpensive methods to resist corrosion. To make a thin film, powders such as epoxy, nylon, and urethane are heated to the metal surface. Metal surfaces are sometimes coated with plastic and wax. Paint serves as a barrier, protecting the metal surface from corrosive compounds’ electrochemical charge.

- Alkalinity to control pH

- Cathodic Protection: This method is used when two different metals are put together and exposed to a corrosive electrolyte. To prevent this, the active sites on the metal surface must be transferred to passive sites by supplying electrons from a different source, usually, galvanic anodes connected to or close to the surface.

Reason Of Boiler Corrosion

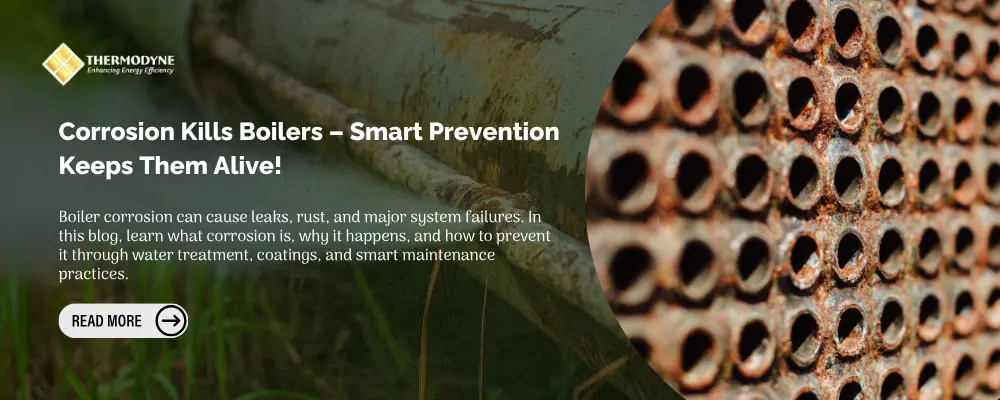

Boiler corrosion is the degradation of a boiler’s metal components due to chemical reactions with water, steam, or other substances. It can lead to serious problems, such as leaks, explosions, and equipment failure.

There are many factors that can contribute to boiler corrosion, including:

- The composition of the water used in the boiler. Hard water, which contains high levels of minerals, is more corrosive than soft water.

- The temperature of the water. The higher the temperature, the more corrosive the water becomes.

- The presence of oxygen in the water. Oxygen can react with the metal in the boiler to form rust.

- The presence of other chemicals in the water. Some chemicals, such as chlorides and sulfates, can also be corrosive.

- The design of the boiler. Poorly designed boilers can be more susceptible to corrosion.

FAQs

Boiler corrosion is the deterioration of a boiler’s metal surfaces due to chemical reactions with its environment.

The most common causes of boiler corrosion are:

Oxygen

Carbon dioxide

Contaminants

High temperatures

Stress

Boiler corrosion can cause a number of problems, including:

Reduced efficiency

Increased maintenance costs

Safety hazards

There are a number of ways to prevent boiler corrosion, including:

Using corrosion-resistant materials

Treating the boiler water

Monitoring the boiler

The signs of boiler corrosion include:

Rust

Pitting

Holes

Leaks

Boiler corrosion can be fixed by:

Repairing the damaged areas

Replacing the affected parts

Treating the boiler water

The cost of fixing boiler corrosion depends on the severity of the damage. In general, it is less expensive to repair minor damage than it is to replace major parts.

The best way to prevent boiler corrosion from happening again is to take steps to prevent it in the first place. This includes using corrosion-resistant materials, treating the boiler water, and monitoring the boiler.

Boiler corrosion can weaken the boiler, which can lead to safety hazards. These hazards include:

Boiler explosions

Boiler fires

Boiler leaks

In some jurisdictions, there are legal requirements for boiler corrosion. These requirements may include:

Regular inspections by a qualified inspector

Repair or replacement of damaged parts

Treatment of the boiler water

Corrosion is the gradual destruction of a material, usually a metal, by chemical or electrochemical reaction with its environment. It is a natural process that can be accelerated by factors such as moisture, oxygen, acids, and salts.