Thermodyne Engineering Systems

Biomass Boilers: Potential of Biofuel Biomass Boilers for Sustainable Energy Solution

Biomass Boilers: Potential of Biofuel Biomass Boilers for Sustainable Energy Solution

Biomass Boilers, biomass heating systems, burn biofuel (generally called as biomass fuel). Biofuels are cheaper than electricity, petroleum oil, or natural gases. Biomass boilers are ideal for year-round heating requirements & hot water needs.

Harnessing the Power of Biomass: Biofuel for Efficient Boiler Systems

Biomass is a renewable energy source that can be used as biofuel in efficient boiler systems. It comes from organic materials like wood chips, pellets, agricultural residues, and energy crops. Biomass is sustainable, continuously replenished through natural processes, and has a near-neutral carbon footprint. Using biomass reduces dependence on finite fossil fuels and has advantages such as lower energy costs, lower carbon emissions, improved energy security, and economic benefits.

Efficient boiler systems maximize heat extraction from biomass through technologies like flue gas economizers, air preheaters, and advanced combustion control systems. These systems also incorporate technologies to minimize harmful emissions like particulate matter and nitrogen oxides.

Combining biomass and efficient boiler systems can result in reduced energy costs, lower carbon footprint, improved energy security, and economic benefits. Challenges include ensuring a consistent supply of biomass, proper storage and handling, higher initial investment compared to traditional boilers, and sustainability concerns like deforestation. However, by addressing these challenges and promoting responsible practices, biomass can play a significant role in transitioning towards a low-carbon future.

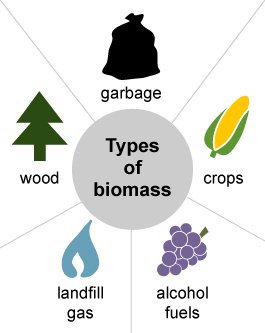

Types of BioFuel

Biomass fuel generally includes wood which may be in the form of wood logs, wood chips or wood pellets. Wood chips and wood pellets can be fed both manually as well as automatically into the furnace while wood logs are mostly fed manually in the boiler. Other forms of biomass fuel include animal waste, household and industrial waste, crops such as maize, willow etc.

Education Project (public domain)

The Biofuels come in various size nd shape. Biomass fuels are gaining huge popularity in today’s world because biomass is cheaper and easily available as compared to other fuels. As people are becoming more and more aware of the benefits of using biomass as a fuel so are we.

Thermodyne Engineering Systems holds a wide experience in manufacturing Biomass Fuel Boilers.

Biomass Boilers for Power Plants Manufactured by Thermodyne

are also known as Combi Boilers are effective in burning biofuels.

Thermodyne Boilers provide automatic feeding of wood chips and wood pellets into an external furnace using rotary feeders or drum feeders. Our rotary feeders are also effective in spreading the fuel equally all over the furnace grate which ensures effective burning of biomass fuel.

This external furnace is enclosed by the water tubes which absorb most of the radiation heat from the combustion of fuel. After leaving the furnace, flue gases enter the tubes where gases flow at high velocity and transfer heat to water using convective heat transfer. Forced draft and Induced draft fans are provided to ensure effective heat transfer using 3 T’s Principle: Time, Temperature and turbulence.

Biomass Boilers: A Sustainable Solution for Commercial and Industrial Heating

Biomass boilers offer numerous benefits as a sustainable and cost-effective heating solution for businesses. They utilise organic materials as fuel, which minimises environmental impact and reduces greenhouse gas emissions. Some of the key advantages of biomass boilers include:

- Environmental preservation: By reducing reliance on fossil fuels, biomass boilers help combat climate change and contribute to environmental preservation. The use of organic materials significantly reduces the carbon footprint of businesses, making biomass boilers a greener choice.

- Cost savings and efficiency: Biomass boilers are highly efficient, converting a large percentage of fuel into heat energy. This results in reliable and cost-effective heating, reducing overall energy expenses for businesses. Additionally, government incentives and grants further enhance the financial appeal of biomass boilers.

- Scaling up for commercial and industrial use: Biomass boilers are suitable for large-scale operations such as office buildings, factories, hotels, and hospitals. They provide consistent warmth while minimising environmental impact, making them an ideal choice for businesses with significant heating needs.

- Showcasing commitment to sustainability: By adopting biomass boilers, businesses can demonstrate their commitment to reducing carbon emissions and promoting renewable energy sources. This positions them as leaders in sustainability, resonating with environmentally conscious consumers and inspiring others to adopt eco-friendly practices.

In addition to these benefits, biomass boilers offer other advantages:

- Fuel availability and security: Biomass fuels, such as wood pellets and agricultural waste, are readily available and promote fuel security by reducing dependence on external sources. They also support local economies by boosting the forestry and agriculture sectors.

- Carbon neutrality and carbon offsetting: Biomass boilers can achieve carbon neutrality when paired with sustainable fuel sources. Carbon dioxide released during combustion can be offset by the carbon dioxide absorbed during the growth of new biomass, minimising the carbon footprint.

- Waste reduction and circular economy: Biomass boilers can utilise various organic waste materials, contributing to waste reduction and supporting a circular economy. By repurposing waste for heat and power generation, biomass boilers reduce landfill usage and associated environmental impacts.

- Renewable Heat Incentive (RHI): Many countries offer renewable heat incentive programs that provide financial support to businesses adopting sustainable heating solutions like biomass boilers. Participating in these programs allows businesses to recover a portion of their investment and benefit from financial incentives.

- Technological advancements and innovations: Continuous development in biomass boiler technology has led to improved efficiency, reduced emissions, and enhanced control systems. Innovative solutions, such as combined heat and power (CHP) systems, maximise energy utilisation and efficiency.

By leveraging the benefits of biomass boilers, businesses can prioritise sustainability, reduce costs, and contribute to a greener future.

Biofuels Pros & Cons of Power Plant Biomass Boiler Fuels

Pros of Biofuels

- Renewable Energy Resources

- Environment-Friendly ( Most Important )

- Cheaper

- Easy Sourcing

- Reduces the need for fossil fuels which are considered as non-renewable resources

Cons of BioFuels

- Occupies Large Space: Biomass fuels have lesser bulk density, biofuels generally require large storage space.

- Large Furnace in Biomass Boilers: Large furnace area and volume are required for biomass fuel combustion.

Types of BioFuels Infographics:

Looking for Biomass Boilers? Contact our sales representatives to know more about Biofuel based Boilers

this article helpful for Buyer and technical skill engineering persons.

Also Read: Boiler Water Treatment Chemicals

9 way to provide sustainable solutionfor industrial biomass boiler

Biomass Boilers FAQ

A biomass boiler is a furnace that burns organic materials, such as wood, wood chips, and agricultural waste, to generate heat. Biomass boilers can be used to heat homes, businesses, and other buildings, and they can also be used to generate electricity.

Renewable energy: Biomass is a renewable resource, which means that it can be replenished over time. This makes biomass boilers a more sustainable option than fossil fuel-fired boilers.

Low emissions: Biomass boilers produce lower emissions than fossil fuel-fired boilers. This is because biomass burns cleaner than fossil fuels, and it does not produce harmful greenhouse gases.

Cost-effective: Biomass boilers can be a cost-effective way to heat homes and businesses. The cost of biomass fuel is typically lower than the cost of fossil fuels, and biomass boilers can be more efficient than traditional boilers.

There are two main types of biomass boilers:

Wood-fired boilers: Wood-fired boilers are the most common type of biomass boiler. They are relatively simple to operate and maintain, and they are available in a variety of sizes.

Pellet-fired boilers: Pellet-fired boilers burn wood pellets, which are a type of biomass fuel that is made from compressed wood waste. Pellet-fired boilers are more efficient than wood-fired boilers, and they produce lower emissions.

The most common fuels used in biomass boilers are:

Wood: Wood is the most common fuel used in biomass boilers. It is available in a variety of forms, including logs, chips, and pellets.

Agricultural waste: Agricultural waste, such as straw, corn cobs, and manure, can also be used in biomass boilers.

Organic waste: Organic waste, such as food scraps and yard waste, can also be used in biomass boilers.

There are several factors to consider when choosing a biomass boiler, including:

The size of the building to be heated: The size of the boiler will depend on the size of the building to be heated.

The type of fuel to be used: The type of fuel to be used will depend on the availability of fuel in the area.

The efficiency of the boiler: The efficiency of the boiler will affect the amount of fuel that is needed.

The cost of the boiler: The cost of the boiler will depend on the size, type, and efficiency of the boiler.

The installation of a biomass boiler should be done by a qualified professional. The installation process will vary depending on the type of boiler and the location of the installation.

Biomass boilers require regular maintenance to ensure that they operate properly. The maintenance schedule will vary depending on the type of boiler and the amount of use.

There are a few safety concerns associated with biomass boilers, including:

Fire: Biomass boilers can produce hot fires, which can pose a fire hazard.

Soot: Biomass boilers can produce soot, which can be a health hazard.

Combustion gases: Biomass boilers can produce combustion gases, which can be harmful if they are not properly exhausted

The government regulates biomass boilers in order to ensure safety. The regulations vary from state to state, so it is important to check with your local government to find out the requirements.

The U.S. Department of Energy: The U.S. Department of Energy has a website with information about biomass boilers.

The National Biomass Energy Center: The National Biomass Energy Center is a non-profit organization that provides information about biomass energy.

The American Boiler Manufacturers Association: The American Boiler Manufacturers Association is a trade association that represents the biomass boiler industry.